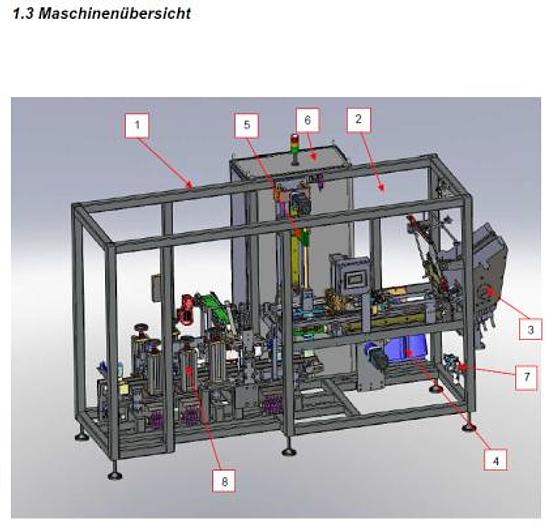

Description

Mohrbach MB PCT Carton Converting Machine – Year 2015

Possible formats of folding boxes:

* 92 * 82 * 95 mm

* 92 * 82 * 75 mm

Machine for assembling and gluing boxes from flat blanks,

as well as for filling boxes, the lid shaping and lid closure.

The feeding of the blanks leaflet is monitored by 2 photocells.

Transport the stored guide rails and with the feed rails horizontally

over the implement folding transported.

Cartoner, make Mohrbach, type MB PCT, year 2015

Possible folding box formats:

92*82*95mm and 92*82*75mm

functional description

Machine for erecting and gluing boxes from flat blanks, as well as box filling, lid forming and lid closing.

The magazine supply for the carton blanks is monitored by 2 photocells. One is for warning

at cutting minimum and the second switches the machine to malfunction when only a few

blanks are available in the magazine.

A cardboard blank is removed from the inclined magazine by means of a vacuum feeder

Transport guide rails stored and with feed rails horizontally over the folding tool

transported. Here, the blank passes the glue station, where hot glue is applied to the cardboard blank

is applied.

After the blank has been transported over the folding tool, it is vertical from the

working insertion plunger pressed through the folding tool opening. The glued

Cardboard sides erected around the ram and due to the special shape of the tool jaws to the

lateral connection flaps pressed and glued.

The erected and glued box is stripped below the tool and into a

including running clock chain with pushing and counteracting carriers sold and to

Transported filling station.

The pyramid bags pre-packaged in a bag are transported from the side via a belt conveyor

supplied, set up and placed in the box using the “toploading” method.

In the following station, the bag is slightly compressed from above via a cylinder,

so that the upper flap of the bag does not protrude over the edge of the box and at the same time the two

Box dust flaps smashed.

Glue is then applied and the front flap is shaped and glued.

At the end of the cycle chain, the finished box is placed on an outfeed conveyor to the left in the direction of travel

pushed off and transported out of the machine.

The reason for the levy is a change of concept. The cartoner also has an infeed and outfeed conveyor and a Robatech gluing system.

Folding boxes were filled with tubular bags, the station for filling the tubular bags is integrated.