Description

OKUMA GENOS M460R-VE – Year 2016

CNC Vertical machining center

Technical specifications

work table dimensions (L x W): 1000 x 460 mm

feed rate in the X/Y/Z axis: 762/460/460 mm

rapid traverse in the X/Y/Z axis: 40/40/32 m/min

maximum spindle rotational speed: 15000 rpm

minimum spindle rotational speed: 50 rpm

rotary table disc diameter: ⌀ 200 mm

maximum tool length: 300 mm

positioning accuracy of the X,Y,Z axis: ± 0.004 mm

positioning repeatability of the X,Y,Z axis: ± 0.0015 mm

spindle taper: BT40

spindle torque: 146-199 Nm

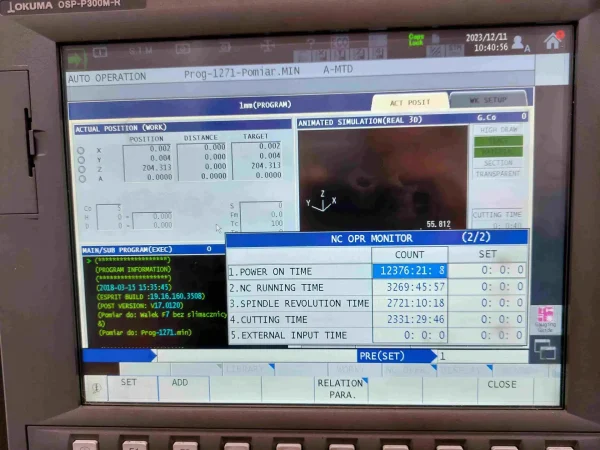

cutting time: 2331 h

machine switch-on time: 12376 h

thermal stabilisation system (spindle): TAS S

thermal stabilisation system (structure): TAS C

vibration-reducing technology: Machining Navi M-g

air purge through spindle during tool change

possibility to set a minimum and maximum drive load for each tool

connection power: 37.5 kVA

power supply: 3x 400 V; 50 Hz

dimensions (L x W x H): 2810 x 2210 x 2746 mm

weight of machine: 6500 kg

Equipment of the OKUMA GENOS milling center

OKUMA OSP-P300M-R CNC control with One-touch IGF Advance graphical programming support overlay and additional G-CODE functions

CAM 3D software: ESPRIT SolidMill

KITAGAWA TMX200 rotary table with 4 axes and manual tailstock

workpiece measuring probe: BLUM

tool measuring probe: BLUM

Eco-Suite software for operating cost management of the machine

32-position tool magazine

tooling (collets, reduction collets, clamping pins for toolholders, holders, milling chucks, vices, etc.)

cooling through spindle 15 bar

chip conveyor

coolant gun

handwheel

Ethernet interface

RS-232 interface

USB port (2 pcs)

OKUMA GENOS M460R-VE CNC Vertical machining center was built in 2016 in Taiwan. This technologically advanced machine was designed with the goal of providing its user high reliability as well as extreme precision, while its extensive machining capabilities will significantly improve any manufacturing process.

One of the many innovative technologies incorporated into the machine is the Machining Navi M-g technology, which computes the most favourable machining parameters for a given job based on an analysis of the acoustic spectrum. The system also levels the vibrations and oscillations that occur at the contact between the tools and the workpiece, resulting in better workpiece surface quality, longer cutting tools life and low load on the main spindle.

In addition, despite the most demanding machining operations, the OKUMA GENOS M460R-VE CNC vertical machining center remains very economical and environmentally friendly thanks to its state-of-the-art Eco-Suite software, which manages the consumption of energy and operating media. As a result, up to 30% energy is saved compared to other machines without such software. The design also includes a thermal compensation system in the form of sensors that analyse the current temperature condition, allowing the controller to automatically respond to changes in the machine geometry.

The OKUMA milling center is offered with an extensive range of equipment, consisting of, among others, the OKUMA OSP-P300M-R CNC control with the One-touch IGF Advance graphical programming support overlay and additional G-CODE functions, a rotary table with 4 axes and a manual tailstock, as well as workpiece and tool measuring probes. The total machine weight is 6500 kg.