Description

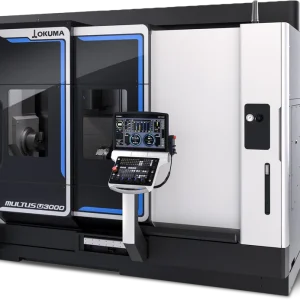

Okuma MacTurn 30 CNC MultiTasking Machine -Year 2000

Manufacturer Okuma

Model Macturn 30 Multi Axis Mill Turn Lathe

Year 2000

Condition Used

Machine Control Okuma OSP 7000L w/ IGF Conversational Programming

Chuck Size 8″ 3-Jaw Hydraulic Chuck

Maximum Swing 21.65″

Maximum Turning Diameter 19.69″

Maximum Center Distance / Maximum Work Length 39.37″ / 39.37″

X-axis travel 16.93″

Y-Axis Travel 7.48″ (+/- 3.74″)

Z-Axis Travel 42.91″

B-Axis Tilt Movement .001 Degree Movement

C Axis Spindle Rotation 0.001 Degree Full C Axis

Spindle Nose / Bore / Bar Capacity A2-6″ / 2.44″ / 2.00″

Main Motor 20 HP

Spindle Speed 35 – 4,500 RPM – 2 Ranges

Milling Spindle Speed 6,000 RPM

Milling Spindle Motor 9 HP

Tool Magazine Capacity 80 Station Tool Changer

Maximum Tool Diameter / Length / Weight 4.33″ / 11.81″ / 22 lbs

Rapid Traverse Rates X, Y / Z 1181 IPM / 1024 IPM / 1575 IPM

Machine Dimensions LxWxH 154″ x 96″ x 91″

Machine Weight 23,275 lbs

Upper B Axis Turret Full Contouring B-Axis Universal Head – .001 Degree

Y Axis Capability

Full C-Axis Spindle Rotation – .001 Degree

H2 Turret which has one side for mill tools and one side for static tools

80 Station Automatic Tool Changer

Tailstock – Tow Along Type

8″ 3-Jaw Hydraulic Chuck

Tool Presetter

IGF Conversational Programming

Chip Blaster EV2000 1900 PSI High Pressure Coolant

Coolant Through the Mill Tools

Chip Conveyor – Concept 2000

In Process Gauging – Probing

Synchronous Tapping

BT-40 Spindle Taper

Tool Life Management

Helical Cutting

Oil Chiller

Coolant System with Tank & Pump

3.5″ Floppy Disk Interface

RS-232 Port Interface – Added MOXA Network Interface to RS-232 as seen in photos

Original Software Disks

All Available Manuals and Tooling (Approximately 50 total holders, 10 of which are for turning)