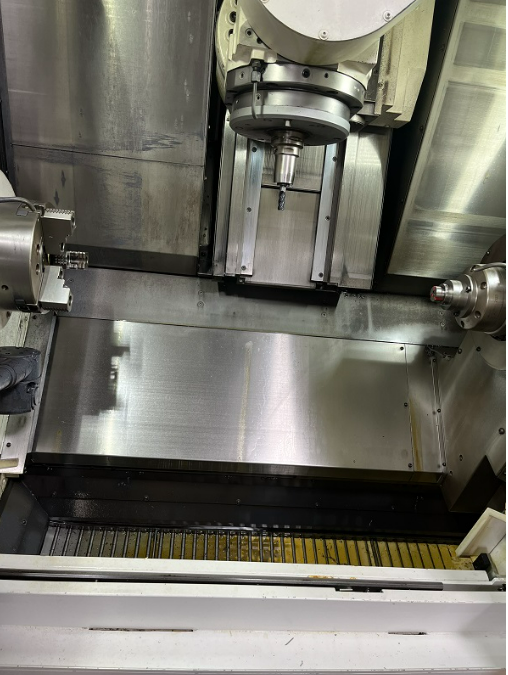

OKUMA MULTUS B250II-1SW/750 ARMROID A201 Robot 3-Jaw built-in robot packaged - Year 2022

Contact us for price

Description

OKUMA MULTUS B250II-1SW/750 ARMROID A201 Robot 3-Jaw built-in robot packaged - Year 2022

X-axis 500.126 mm

Z-axis 800.1 mm

Max workpiece weight 3.99274 kg

Spindle taper A2-6

Spindle bore 61.976 mm

Number of tools on turret 60

Turning speed 5000 rpm

Spindle motor power 22.37136 kW

Tailstock no

Bar feeder no

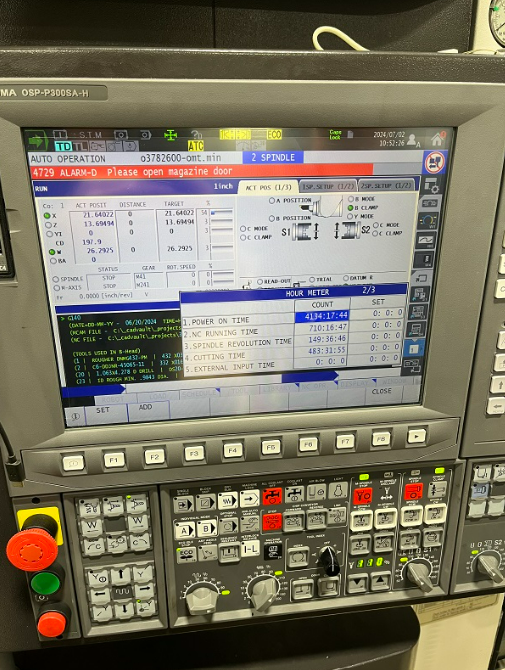

Worked hours 483 hours

Hours under power 4134 hours

OSP-P300SA-H, 2.6″ Bar, 8″ Chuck, 5000 RPM, 30 HP, H1 Spindle, Y-Axis, Sub Spindle, Armroid A201 Robot, (6) Stations, Touchsetter, Chip Conveyor, Pristine

Product Details

Chuck Size 8″

Max Diameter Bar Capacity 2″

Spindle Motor 30 / 20 HP

Spindle Speed 5000 RPM

Spindle Nose A2-6

Spindle Bore 2.44″

Tools 60

Sub Spindle Chuck Size 6″

Sub Spindle Motor 15 / 10 HP

Sub Spindle Nose 140 mm Flat

Sub Spindle Speed 6000 RPM

Rapid Traverse Rates

(X & Z / Y / W) 1575 / 1023 / 787 ipm

X-Axis Travel 19.69″

Z-Axis Travel 31.5″

Y-Axis 7.87″

C-Axis Index (Left & Right Spindles) .001 Degrees

Distance Between Spindles 40.55″

H1 Index 0.001 Degrees

H1 Spindle Speed 50 – 12000 RPM

H1 Swivel 225 Degrees

Max Tool Diameter 3.54″ / 5.12″

Max Tool Length 7.87″

Max Tool Weight 8.8 lbs.

Max Turning Diameter 23.62″

W-Axis Travel (Sub Spindle) 31.89″

Product Features

OKUMA OSP-P300SA-H CNC Control

12.1″ Color TFT

USB Port

H1 Upper Tool Spindle

Programmable Sub Spindle

Kitagawa 8” BB208 Hydraulic Chuck Left

Kitagawa 6” B206 Hydraulic Chuck Right

NC B-Axis with Contouring

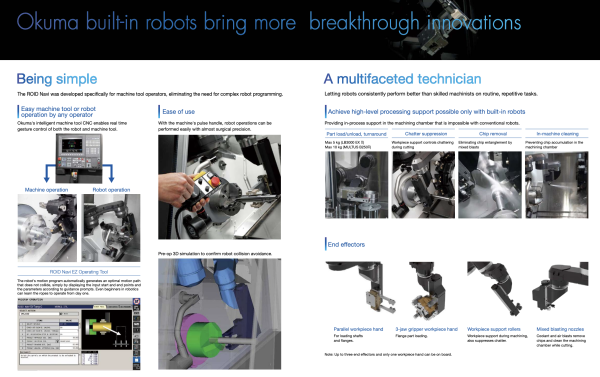

Armroid A201 Robot 3-Jaw Spec

Work Stocker 6 Station Lift Up Type

End Effector Stocker 3 Station

End Effector Work Support Roller

5-Axis Machining Kit

High Precision C-Axis Both Spindles

Spindle Motor Upgrade 30 HP Left

60 Tool Magazine (Capto C6)

Auto Gauging Renishaw RMP600 RMI-Q Capto C6

Renishaw Inspection Plus Software with GUI – Lathe

Y-Axis Gauging with Slope Gauging

Z-Axis Auto Zero Offset Function Both Spindles

C-Axis Auto Zero Offset Function Both Spindles

Touchsetter Auto, Touch Sensor Gauging Interface Renishaw RMI-Q

Lathe Tool Index Function Multi Edge 12 Position

Chip Conveyor Right Discharge Drum Filter High 750

C-Axis Torque Skip Function Both Spindles

Constant Surface Speed for Y-Axis

Additional Light OKUMA Logo

Coolant Splash Gun

Lubrication Monitor B-2

User Task III

10 MB Program Cap

Three Color Tower Light

Manufacture Date May 2022

4134 Power On Time

710 NC Running Time

149 Spindle Revolution Time

483 Cutting Time

ARMROID was born from a perfect union of machine tool and robotic engineering. This next-generation robot

system can fundamentally change the various issues facing manufacturing. By doing the work that was

previously done by human hands, the robot will perform every job imaginable, increase productivity overall,

and deliver on its promise to be the key player in tomorrow’s production systems.

That automation will enable humans to perform higher value-added activities, and focus on future challenges.

This is what Okuma is proposing.