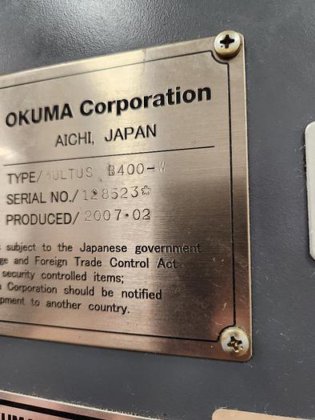

Okuma Multus B400-W – Year 2007

Contact us for price

Description

Okuma Multus B400-W – Year 2007

Okuma Multus B400-W Multi-Axis CNC Turning Center

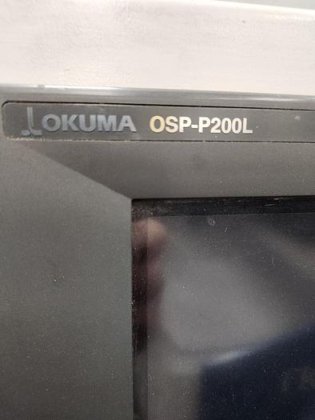

CNC Control: yes

Type of CNC Control: OSP-P200L Control

# Axis: 6

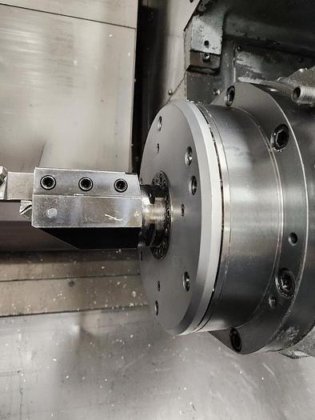

Chuck Size: 15 inches Kitagawa B215 Chuck

Turning Diameter: 26.37 inches

Center Distance: 60.83 inches

Spindle Bore: 5.91 inches

X Axis Travel: 27.17 inches

Z Axis Travel: 60.83 inches

Y Axis (Yes / No): yes

X Axis Rapid Feedrate: 1575 inches-per-minute

Z Axis Rapid Feedrate: 1575 inches-per-minute

Spindle Speed (RPM): 2800

Main Motor: 40/30

Sub Spindle Chuck Size: 12 inches

Sub Spindle Speed (RPM): 3800

Sub Spindle Motor: 30/20

Live Milling (Yes / No): yes

Live Milling Speed (RPM): 10000

Live Milling Motor: 27

Turret Capacity: 80

Tailstock (Yes/No): yes

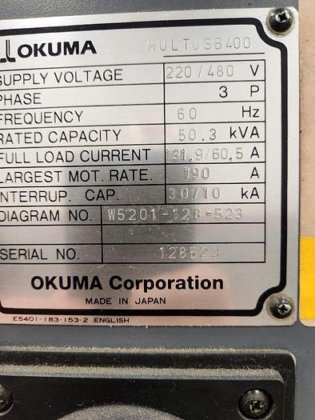

Dimensions: 227 x 107 x 118

Weight: 32000 pounds

Spindle Nose: A2-11

Travels: X-27.17″, Y-9.06″, Z-60.83, W-61.06″

B Axis Head Tilt: -30 Degree to 195 Degree

C Axis Index: 0.001 Degree

Live Tooling Taper: CAPTO C6

Renishaw Probing

Tool Presetter

Chip Conveyor

Sub Spindle w/ 12″ Kitagawa B212 Chuck

Chipblaster, Mist Collector

Machine comes loaded with tooling

The Okuma Multus B400W stands as a pinnacle of engineering excellence in the realm of multi-tasking CNC machines. This model is crafted to meet the diverse needs of modern manufacturing, making it an ideal choice for industries where precision and versatility are paramount, such as aerospace, automotive, and complex component production. The Multus B400W distinguishes itself by integrating various machining operations – including turning, milling, drilling, and tapping – into one seamless and efficient workflow, thereby streamlining production and enhancing operational efficacy.

Key Technical Specifications

Control System: Equipped with Okuma’s OSP-P control system, the Multus B400W offers sophisticated and user-friendly programming capabilities, facilitating complex machining tasks.

Spindle Configuration: The machine boasts a powerful main and sub-spindle, capable of handling demanding machining tasks with precision.

Tool Magazine: A large capacity tool magazine enhances the machine’s ability to execute diverse machining operations without frequent tool changes.

Axis Capability: Advanced multi-axis functionality allows for precise and intricate machining of complex parts.

Technical Data

Key features of the Okuma Multus B400W include:

Integrated Machining Capabilities: Combines turning and milling in a single setup, greatly reducing production times and improving efficiency.

Thermal Stability: Incorporates advanced thermal compensation technology, maintaining machining accuracy over extended operation periods.

Robust Design: The Multus B400W’s sturdy construction ensures durability and consistent performance under demanding industrial conditions.