Paglierani FS-368 Combi Monoblock Bag-Filling Machine For Open-Mouth Bags Bagging Line

Contact us for price

Description

Paglierani FS-368 Combi Monoblock Bag-Filling Machine For Open-Mouth Bags Bagging Line

completely automatic bagging solution for open mouth bags in paper, raffia, or plastic. With weighing unit and fishbein sewing unit

With Palletizing robots TMG Impianti

Capability to pack approximately 1000-1200 bags per hour, depending on the palletization scheme, bag size, and quantity per level The palletizer can work both 1000 1200 Euro pallet 800 1200 formats ¨

Comes also with Automatic turn arm pallet wrapper

Manufacturer Catalogue Information about Paglierani FS-368 Combi Monoblock Bag-Filling Machine For Open-Mouth Bags :

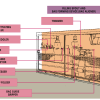

The FS368 COMBI monoblock bag ging machine is the fully automatic solution for the filling of open-mouth bags.

COMPACT:all machine operations, including empty bag positioning, filling and closure (by stitching, sealing or both) take place in a space just 3,2 m long and 2,3 m wide (version with stitching only or

sealing only).

RELIABLE:the entire filling procedure (bag mouth forming and closing) is assisted by a gripper system which holds the top of the bag through every stage, never releasing the bag from the moment of pick-up.

VERSATILE:the filling machine is able to pack bags made of widely varying materials (paper, woven or laminated polypropylene, polyethylene).

SIMPLE:robust design, conceived to meet the highest performance standards, easy to operate and maintain.

SAFE:intrinsic guarding provides safe working environment whilst allowing easy access though sliding doors, for maintenance.

HIGH PERFORMANCE:the electronic control systems enable the bag-filling machine to achieve high producti

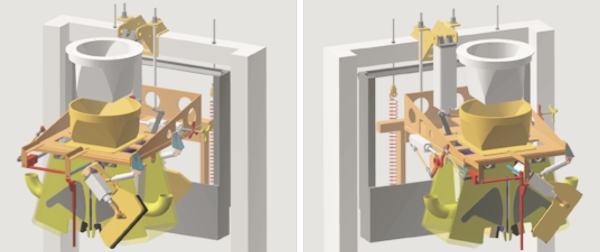

FILLING SPOUT

AND FORMING DEVICE FOR FLAT BAGS

(BAG ALIGNER)

The filling spout is adjustable for bags of different widths. Bag presence sensors ensure that filling only takes place when the bag is correctly positioned. The forming device (bag aligner) is part of the filling spout and ensures perfect alignment of the bag top. No adjustment is required in case of variations in bag size. Dust guard baffles and dust extraction connections ensure a dust-free environment during filling operations. The full bag is placed on the conveyor belt ready for removal by a pneumatically operated raising and lowering movement.

As an optional extra, parts in contact with the product can be in stainless steel.

VERSION FOR

GUSSETED BAGS

For gusseted bags, the feeding system and the filling outlet are equipped with pneumatic grippers which hold the gusset closed, ensuring it keeps its shape. The mouth of the bag is opened and the gusset is kept closed by side grippers (A). After positioning at the filling outlet, the bag is kept with its gussets closed and correctly shaped (B).

PICK AND

PLACE ARM

The bag is picked up from the stack by the bag pick up arm, which moves in an arc to place it onto the filling spout driven by a rod and crank coupling. Precise high speed operation is guaranteed by the encoder controlled variable speed motor.

BAG PICK-UP

The empty bag is picked up and opened by suction cups. Suction is provided by a Venturi or vacuum pump in the case of plastic and woven polypropylene bags.

BAG MAGAZINE

The standard machine has a bag magazine for three stacks of bags, each 200 mm high. Empty bags can be added at any time without stopping production. No adjustments are required for variations in bag length, while changes in width involve quick adjustment. If the supply of bags runs out, the machine stops and the operator is alerted by a beeper and/or flashing warning lamp.

FRAME

Constructed of rolled hollow section carbon steel* members, the FS368 COMBI monoblock bag-filling machine has a rigid, solid structure which:

• minimizes the points where dust can build up, in compliance with food standard hygiene requirements • houses and protects all electrical wiring and compressed air lines inside the structure.

* Special version in

AISI 304 stainless steel.

SAFETY FENCES

In accordance with current safety guide lines, the machine includes sliding safety fences, which trigger an emergency and an immediate stoppage when opened.

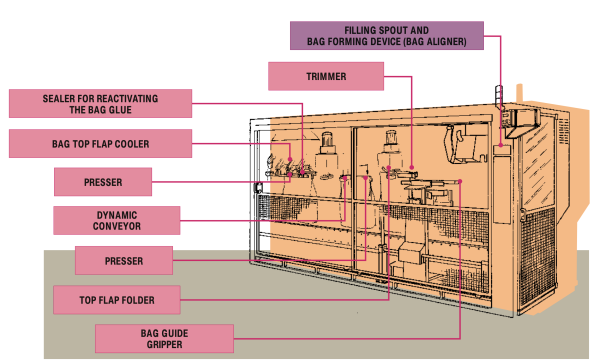

BAG TOP GRIPPER AND

TRANSFER CARRIAGE

After filling, stretching and alignment, the bag is held close to its mouth and transported by the transfer carriage to the entry point of the dynamic conveyor (closing system). The gripper operates pneumatically, while carriage travel is mechanically driven (motor-reduction gear-chain) at a variable speed electronically controlled by a programmable frequency drive. No adjustment is necessary when changing bag sizes.

CONVEYOR BELT

The full bag is transported on a motor driven conveyor. Adjustment of the conveyor height is electrical and automatic; during the switch from one bag size to another, the height of the conveyor is controlled by an encoder.

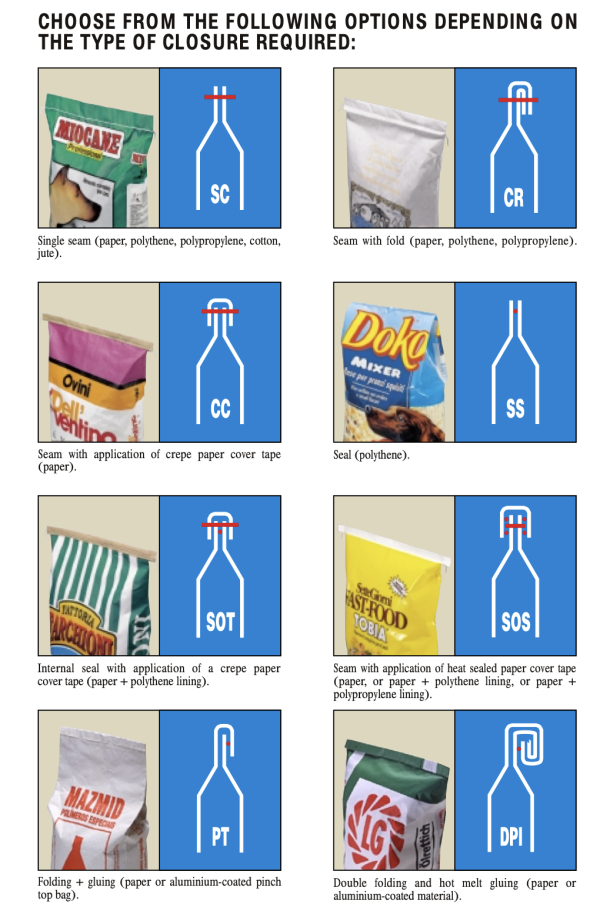

VERSION FOR SEALING + SEWING

SOT type closing: internal seal with application of a crepe paper cover tape.