Description

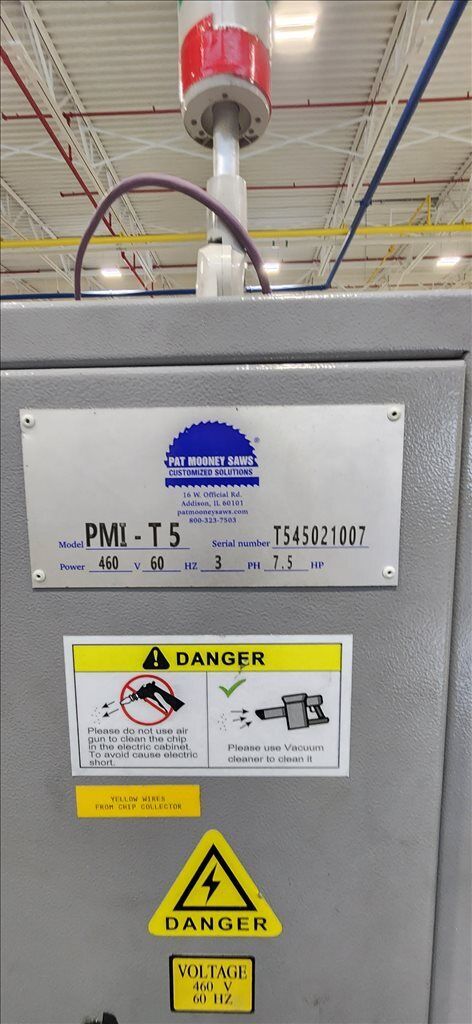

PAT MOONEY PMI-T5

CNC Automatic Double Head Compound Miter Upcut Saw

For 90° Cuts: 5.9″ x 10.2″

For 45° Cuts: 3.54″ x 10.2″

Max Cut Length: 177.2″ (opt. 236.2″)

Min Cut Length (Table at 90°/Saw 90° Tilt): 24.2″

Min Cut Length (Table at 45°/Saw 45° Tilt): 36.6″

Min Cut Length (Table at 67.5°/Saw 45° Tilt): 43.3″

Blade Size: 22″ D x 1″ Bore x 120 T

Precision of Cutting Length: +/- 0.006″

Precision of Cutting Angle: +/- 0.15°

Range of Rotation Angle: 22.5°~90°~157.5° (+/-0~67.5°)

Rotating Speed of Main Motor: 2800 RPM

Power of Main Motor: 7.5 hp x 2

Manufacturer Catalogue Information about PAT MOONEY PMI-T5 :

PMI-T5 Automatic Double-Sawhead Machine

Compound Miter

The PMI-T5 is an automatic double sawhead machine is designed to cut aluminum

profiles and other non-ferrous materials. The machines two saw heads tilt and rotate so it

is capable of completing compound miter cuts. The two saw heads can work

simultaneously or independently. The upcut style saw heads are equipped with 24 inch

diameter saw blades. All programming is completed on the machine’s easy-to-use

touchscreen control.

Machine Features:

Two Saw Head Design:

The PMI-T5 is equipped with two saw heads. One of the saw heads is fixed and one is

moveable, so it can be programmed to a cut length. The moveable saw head

automatically positions to the programmed cut length and it moves on dual precision

linear guideways to ensure accurate movements. The saw heads can work

simultaneously or independently.

Saw Head Tilt:

The fixed saw head will tilt 45 degrees to the right and the moveable saw head will tilt 45

degrees to the left. The tilt position is servo controlled on both saw heads. The operator

simply enters the required tilt position for each head into the touchscreen control and they

automatically move to the entered dimensions.

Saw Head Rotation:

The fixed and moveable saw head will rotate 67.5 degrees to the left and right. The

rotation position is servo controlled on both saw heads. The operator simply enters the

rotation position for each head into the touchscreen control and they will automatically

move to the entered dimensions.

Moveable Saw Head:

The moveable saw head’s position is servo controlled so it can be set to automatically

move to a programmed cut length. The entire saw head moves on dual precision linear

guideways. It is available in 177 inch (4.5m) and 255 inch (6.5m) working lengths. The

moveable saw head can be used as a automatic indexing vise so material is being moved

to a programmed cut length and cut on the fixed saw head.

Saw Motor:

Each saw head is equipped with a 7.5 HP saw motor.

Feed Rate Control:

The saw blade feed is controlled via a pneumatic cylinder with full control of the feed

rate. This allows for accurate cuts and long blade life. In addition, the saw blade travel is

controlled for fastest cycle time.

Material Clamping:

The pneumatic clamping system has adjustable clamping pressure to prevent distortion of

thin wall profiles. Each saw head is equipped with vertical and horizontal clamping on

the infeed and outfeed sides of the saw blades.

Precise Micro-Drip Blade Lubrication System:

The saw blades are lubricated via a micro-drip system. A small amount of lubricant is

introduced to an air line at the point of discharge for control and economical distribution

of the saw lubricant.

Saw Blade Enclosure:

The saw blades are fully enclosed underneath the saw cabinets. All access doors are

protected with safety switches.

Technical Specifications:

Servo Motor – Tilt Angle 1 kw (2)

Servo Motor – Rotation Angle 750w (2)

Servo Motor – Moveable Saw Head 1 kw (1)

Tilt Angle – Fixed Saw Head 45 degrees to right

Tilt Angle – Moveable Saw Head 45 degrees to left

Saw Head Rotation (both saw heads) +/- 67.5 degrees

Saw Motor 7.5 HP (2)

Saw Blade Diameter 24”

Saw Blade Speed 1800 RPM

Working Lengths available 14.75ft or 21.32 ft (4.5m or 6.5m)

Dimensions 244” x 72” x 75” (length is 323” for 6.5m machine)

Machine Weight 14.75ft working length – 8,580 LBS

21.32 ft working length – 9,680 LBS