Description

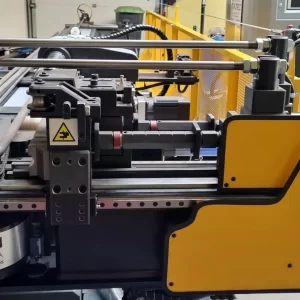

PINES CNC-100 HYBRID CNC TUBE & PIPE Bender – Year 2017

MOTOR 40 HP 30KW

STEEL TUBING Y.P. TO 40,000 PSI 4″ X .109″

OPERATING PRESSURE 2000 PSI

STAINLESS STEEL Y.P. TO 60,000 PSI 4″ X .065″

RESERVOIR CAPACITY 100 GALLONS

NON-FERROUS TUBING Y.P. TO 25,000 PSI 4″ X .188″

WEIGHT 4500 LBS

STEEL PIPE SCHEDULE 80 2.5″

STANDARD BEND RADIUS TO CENTERLINE 12″

STANDARD MAX. TUBE LENGTH OVER MANDREL 136″

STANDARD CARRIAGE TRAVEL 72″

CARRIAGE TRAVEL (Y MOTION) +- .005″

COLLET ROTATION (B MOTION) +- .10 DEGREES

BEND ARM ROTATION (C MOTION) +- .10 DEGREES

BEND ARM ROTATION 195 DEGREES

COLLET ROTATION 360 DEGREES

OVERALL LENGTH 226″

LENGTH OF ARM 38″

BED LENGTH 188″

CENTERLINE HEIGHT 3″

UNDERNOSE CLEARANCE 30″

WORKING HEIGHT 42″

MAXIMUM BEND ANGLE (+ALLOWANCE FOR SPRING BACK) 180 DEGREES

MAX BEND ARM ROTATION 195 DEGREES

OVER-MANDREL TUBE LENGTH 136″

BENDING ARM SPEED 21 RPM

MACHINE EQUIPPED WITH

$38000 WORTH OF TOOLING 120 INCH BASE EXTENSION SWING AWAY WIPER DIE HOLDER HITCH FEED SPRINGBACK COMPENSATION DUAL SPINDLE SWING ARM PDI ZONE RECAPTURE WIPER DIE HOLDER LASER SAFETY SCANNER QUICK DISCONNECT MANDREL ROD REMOTE OPERATOR CONTROL STAND COUNTER CLOCKWISE ROTATION MANDREL EXTRACTOR WITH MANDREL ROD HEAVY DUTY AUTOMATIC MANDREL LUBRICATOR TWIN OVERHEAD TIE BARS FAN COOLED HEAT EXCHANGER HYDRAULIC INLINE PRESSURE DIE ASSIST INDEPENDENT CLAMP & PRESSURE DIE OPERATION (INDEPENDENT TOOLS) AUTOMATIC SLIDE LUBRICATOR FAN COOLED HEAT EXCHANGER

MACHINE DESCRIPTION

Used Pines CNC-100. This pre-owned Tube Benders is in great working condition and can be securely delivered to your facility floor.

Manufacturer Catalogue Information about PINES CNC-100 HYBRID CNC TUBE & PIPE Bender Machine:

CNC – Heavy Duty Pipe Bending Machine Specifications

|

Machine Model |

CNC040 |

CNC075 |

CNC100 |

|

|

MACHINE CAPACITY |

||||

|

Steel tubing, Y.P. to 40,000 PSI |

Inches |

1 1/2” x .109” |

3” x .109” |

4” x .109” |

|

Millimeters |

28 x 2.75 |

75 x 2.75 |

100 x 2.75 |

|

|

Stainless steel, Y.P. to 60,000 PSI |

Inches |

1 3/8” x .065” |

3” x .065” |

4” x .065” |

|

Millimeters |

35 x 1.65 |

75 x 1.65 |

100 x 1.65 |

|

|

Non-ferrous tubing, Y.P. to 25,000 PSI |

Inches |

1 1/2” x .188” |

3” x .188” |

3” x .188” |

|

Millimeters |

38 x 4.75 |

75 x 4.75 |

100 x 4.75 |

|

|

Steel Pipe, Schedule 80 |

Inches |

1” |

2” |

2.5 |

|

Millimeters |

25 |

50 |

63 |

|

|

Standard bend radius to centerline |

Inches |

4 1/2” |

12” |

12 |

|

Millimeters |

113 |

300 |

300 |

|

|

Standard Max. tube length over mandrel |

Inches |

120” |

120” |

136 |

|

Meters |

3 |

3 |

3.5 |

|

|

Standard Carriage Travel |

Inches |

72 |

72” |

72 |

|

Meters |

1.85 |

1.85 |

1.85 |

|

|

BEND ANGLE REPEATABILITY |

||||

|

Carriage Travel (Y Motion) |

Inches |

± .005” |

± .005” |

± .005” |

|

Millimeters |

± .125 |

± .125 |

± .125 |

|

|

Collet Rotation (B Motion) |

±.10 deg. |

±.10 deg. |

±.10 deg. |

|

|

Bend Arm Rotation (C Motion) |

±.10 deg. |

±.10 deg. |

±.10 deg. |

|

|

STANDARD MACHINE SPECICATION |

||||

|

Bend Arm Rotation |

Degrees |

195 deg. |

195 deg. |

195 deg. |

|

Collet Rotation |

Degrees |

360 deg. |

360 deg. |

360 deg. |

|

Overall Length |

Inches |

162 |

220 |

226 |

|

Milimeters |

4,121 |

5,588 |

5,740 |

|

|

B. Length of Arm |

Inches |

48 |

36 |

38 |

|

Milimeters |

1,219 |

914 |

965 |

|

|

C. Bed Length |

Inches |

192 |

185 |

188 |

|

Milimeters |

4,864 |

4,686 |

4,775 |

|

|

D. Centerline Height |

Inches |

1.63 |

2 |

3 |

|

Milimeters |

41 |

51 |

51 |

|

|

E. Undernose Clearance |

Inches |

11 |

22 |

30 |

|

Milimeters |

275 |

559 |

749 |

|

|

F. Working Height |

Inches |

31 |

41 |

42 |

|

Milimeters |

781 |

1,029 |

1,054 |

|

|

Maximum Bend Angle |

Degrees |

180 |

180 |

180 |

|

(+allowance for spring back) : |

||||

|

Over-Mandrel Tube Length : |

Inches |

119 |

156 |

136 |

|

Milimeters |

3,023 |

3,962 |

3,454 |

|

|

Bending Arm Speed : |

RPM |

30 |

14 |

21 |

|

Motor : |

HP |

15 |

20 |

40 |

|

Kw |

11 |

15 |

30 |

|

|

Operating Pressure : |

PSI |

1,000 |

2,000 |

2,000 |

|

bar |

69 |

138 |

138 |

|

|

Reservoir Capaicty : |

Gallons |

41 |

55 |

100 |

|

Litres |

181 |

242 |

440 |

|

|

Weight : |

Pounds |

2,750 |

4,400 |

4,500 |

|

kilograms |

606 |

970 |

992 |

|

HYBRID CNC TUBE & PIPE BENDERS

Hybrid benders are the backbone of the CNC tube bender industry. Rugged and reliable, they are built for the long haul, delivering quality parts year after year. These machines feature a classical hydraulic bending system and electric servo control for the Y and B axis. Hybrid machines can be individually configured to meet your specific bending requirements. Equipped with the Pines TS2000 Series CNC bender control, they are simple to learn and simple to operate. While less feature driven than their fully electric counterparts, they offer an economical introduction into the world of CNC tube bending.

CNC 100

Configuration

The Pines CNC 100 is built with the following standard equipment:

Counter clockwise rotation

1xD bend capability

Inline pressure die assist (PDA) and master bar

Clamp die holder

Mandrel extractor

Automatic mandrel lubricator

Standard wiper die holder

Overhead tie

Laser safety scanner

Automatic slide lubricator

Fan cooled heat exchanger

Servo controlled swing arm (proportional valve)

TS CNC touch screen control system

Dual palm remote operator control

Independent clamp and pressure die close

Many options are available to customize the machine. Including but not limited to:

Electric control options (swing arm, stationary arm, mandrel exactor, PDA)

Quick change tools – Electric servo motor programmable clamping

Base extensions for increased tube over mandrel length

Multi-stack

Split die actuator

Swing away wiper die holder

Square tube package

Clockwise rotation

Long arms

Features

Hitch feed

PDI zone recapture

Springback compensation

Simultaneous motion of Y & B axes

Drop away clamp or dual spindle

Open collet bending

Automatic & Semi-automatic Mode

Early mandrel extract

Part program entry from XYZ, or YBC data

Part program data conversion to or from XYZ or YBC

Part program data conversion to or from absolute or incremental

Part program storage on hard disk or USB memory stick

Part program reversal and mirror image conversions

Graphic display of the part with ability to rotate in any direction

Capacities

Round tubing, mild steel Y.P. to 40,000 psi – 4” x .109

Round tubing, non-ferrous Y.P. to 25,000 psi – 4” x .188

Round tubing, stainless steel Y.P. to 60,000 psi – 4” x .065

Steel pipe, 2.5 IPS schedule 80

Square tubing, mild steel – 2” x .125

Specifications

Maximum standard radius – 12”

Minimum radius to diameter ratio – 1

Centerline height – 2.5”

Maximum bend angle – 195º

Bend arm repeatability – +/- .1º

Carriage repeatability – +/- .005”

Standard tube length over mandrel – 136”

Bend arm speed – 21 RPM

B-axis travel: 360º – Speed: 30 RPM

Y-axis travel: 6’ – Speed: 2400 IPM

Motor horsepower – 40HP

Dimensions – ~ 18.8’ L x 6’ W x 5’ H

Working height ~ 42”

Voltage – 480 3 phase 60 Hz. 45 amp circuit required (220/3/60 @ 75 amps also available)

Weight – Approximately 4500 lbs

Oil reservoir – Completely sealed reservoir with 100-gallon capacity

Safety Features

Safety plates protecting both bend and return sides of swing arm

All electrical components in power panel are “finger-safe” and are in accordance with NFPA standards

Machine is labeled with pinch and hazard points

Two-hand control, manual and automatic

Programmable safety zone covering bend arm path