Description

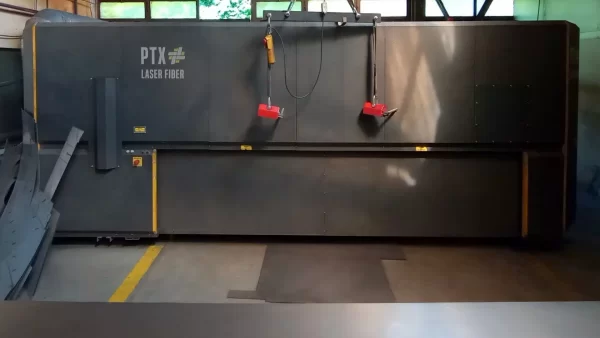

PTX X1 Laser Cutting Machine – Year 2019

Technical specifications of the PTX X1 laser cutting machine

laser beam power: 1.5 kW

number of axes: 4 (X1, X2, Y, Z)

feed rate in X1, X2 axes: 3000 mm

feed rate in Y axis: 1500 mm

feed rate in Z axis: 150 mm

worktable surface (L x W): 3000 x 1500 mm

maximum sheet thickness (black steel): 10 mm

maximum sheet thickness (stainless steel): 4 mm

maximum sheet thickness (aluminium): 1.5 mm

maximum sheet thickness (brass): 1 mm

maximum sheet thickness (copper): 1 mm

maximum workpiece weight: 3200 kg

positioning accuracy: ± 0.005 mm

repetition accuracy: ± 0.15 mm/m

working speed: 50 m/min

acceleration: 1900 mm/s2

extending table speed: 1-9 m/min (continuously adjustable)

total power requirement: 12 kW

extractor fan power: 5.5 kW

extending table power: 1.5 kW

booster gas pressure (oxygen): 0.2-10 bar

booster gas pressure (nitrogen): 0.2-20 bar

power supply: 3x 400 V; 50 Hz

dimensions (L x W x H): 5800 x 2800 x 2100 mm

weight of machine: 4800 kg

Equipment of the PTX X 1 laser cutting machine

CAD/CAM software: Neron CNC Cad

laser source: MAXPHOTONICS

servo motors in each axis

slideways: HiWin

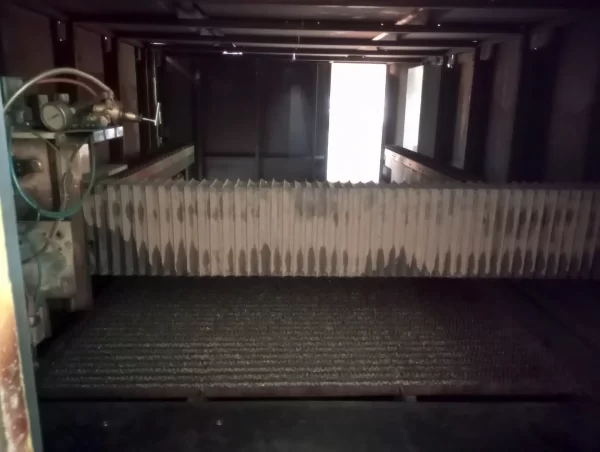

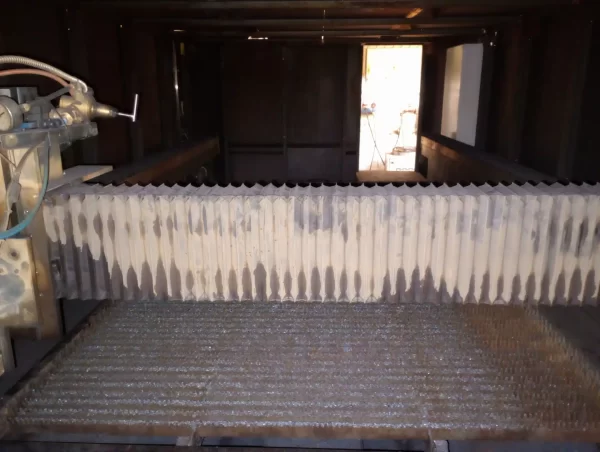

3-section extraction table

planetary gears

mechanically extending table

absolute encoder

PTX X1 fiber laser built in 2019 in Poland is used for cutting sheet metal made of black steel, stainless steel, brass and copper. The laser cutting machine of compact design made of thick-walled welded profiles, uses a special fibre-optic beam with a power of 1.5 kW and a thickness of just a few μm, which results in high productivity and excellent machining precision. State-of-the-art fibre-optic technology also reduces the risk of optics contamination and beam quality degradation, guaranteeing uninterrupted and reliable operation throughout the entire service life.

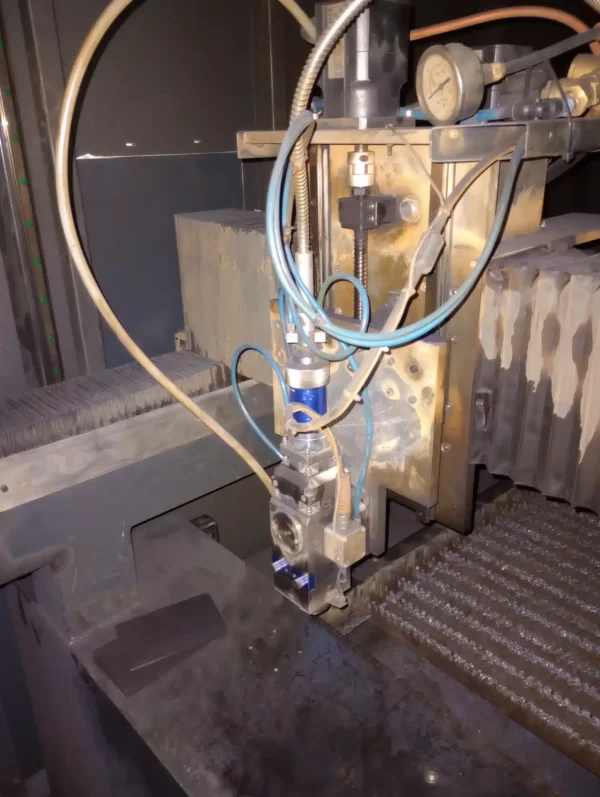

Used with the machine a reliable source MAXPHOTONICS has a special mirror system. These mirrors define the beam lengths which, emitted from concentrated, high-powered diodes, create pump power and actively excite the fibre optics. The beam then enters a specially designed cutting head with adjustable focusing (focus), providing the user with high quality and precision cutting.

The sheet metal cutting takes place on a mechanically extendable work table with a length of 3000 mm and a width of 1500 mm, which allows easy loading and unloading of sheets with a maximum weight of 3200 kg. During machining, the fiber laser X1 maintains very good acceleration/deceleration parameters, high accuracy and high traverse dynamics, thanks to the equipping of all 4 axes (X1, X2, Y, Z) with servo drives with double HiWin slideways and planetary gears.

In order to guarantee maximum operational safety, the laser structure has been enclosed in a closed cabin with windows covered with a special coating, protecting the operator from the harmful effects of the laser beam radiation. In addition, the laser cutting machine is also equipped with a 3-section extraction table that effectively eliminates the contamination generated during processing. The PTX fibre laser weighs 4800 kg.