Description

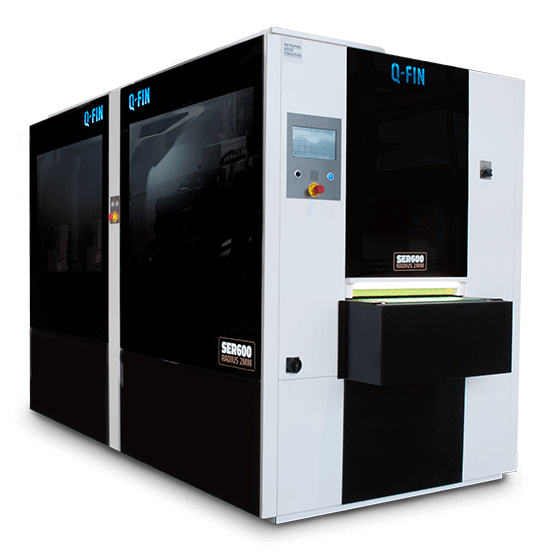

Q-Fin Quality Finishing Machines SER600 -Year 2021

Edge Round Machine with Slag Removal and Suction/Filter Unit

Manufacturer : Q-FIN Quality Finishing Machines

Model : SER600

Year of manufacture : 2021

Technical details

dimensions (l x w x h) approx.

4,000 x 1,600 x 2,100 mm

weight approx.

4,000 kg

Item description

Working height: 900 mm

Minimum dimensions workpiece: 50 x 50 mm

Minimum height workpiece: 0.6 mm (L and W ≥ 5 x H)

Maximum height workpiece: 170 mm

Maximum width workpiece: 600 mm

Conveyor belt speed Frequency control adjustable: 0.3 – 10 m¹/min

Operation HMI touch screen on the front

Optional suction unit WES6000

Control via the deburring machine or via the extraction unit itself

Connection of the suction unit: 1x Ø 300 mm + 1x Ø 200 mm

Prescribed suction capacity: 6000 m3/h

Prescribed suction speed: 19 m/s

Agregate:

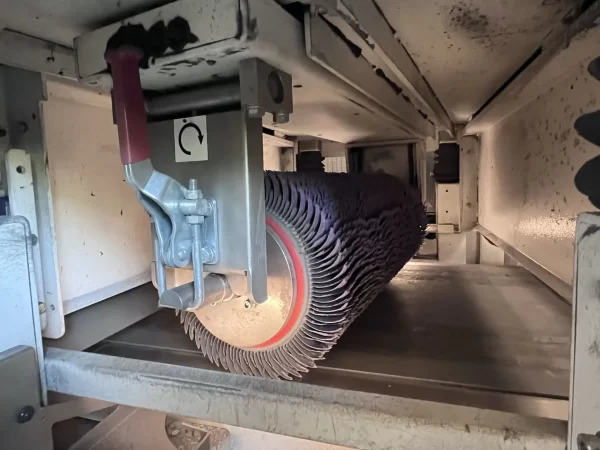

Number of work stations: 5 Aggregates: 1x sanding belt + 4 disc brushes + 2 brush rollers

Sanding belt width: 630 mm

Quick release fastener

Brushes: 4 disc brushes, Ø 255 mm

Brushing rollers: 2 pcs, Ø 350 mm

Including 2 conveyor belts:

Belt width: 800 mm

Belt length: 5200 mm and 1540 mm

DS 600 slag removal machine

Manufacturer Catalogue Information about Q-Fin Quality Finishing Machines SER600 :

|

General Unit SER600 with Magnet system |

|

Authentication CE-approved |

|

Weight kg 3,560 kg |

|

Dimensions L x W x H mm 3640 x 1585 x 2085 mm |

|

Work height mm 900 mm |

|

Minimum workpiece size mm 50 x 50 mm |

|

Minimum workpiece height mm 0.6 mm (L and W ≥ 5 x H) |

|

Maximum workpiece height mm 170 mm |

|

Maximum workpiece widht mm 600 mm |

|

Conveyor belt speed m/min Frequency control adjustable 0.3 – 10 m1/min |

|

Operation panel HMI Touchscreen |

|

Optional Wet Extraction System WES6000 |

|

Connection Wet Extraction System mm 1x Ø 300 mm + 1x Ø 200 mm |

|

Prescribed Extraction Capacity m3/h 6000 m3/h |

|

Prescribed Extraction Speed m/s 19 m/s |

|

Aggregates |

|

Number of stations 5 aggregates: abrasive belt / 4x disc brushes / 2x round brushes |

|

Abrasive belt mm Grinding belt 630 mm wide Quick change system |

|

Brushes mm 4x disc brushes, Ø 255 mm 2x round brushes, Ø 350 mm |

|

Transportation |

|

Conveyor belt version °C EPDM friction rubber, heat resistant up to 140 °C |

|

Conveyor belt set-up kW Equipped with Magnet fixation |

|

Maximum transport conveyor load kg 300 kg |

|

Cleaning conveyor belt Cleaning brush with dust collector |

|

Setting workpiece height Transport table electric adjustable with digital reading |

|

Components |

|

Grinding unit Frequency controlled grinding head with sanding drum |

|

mm Grinding belt size: 630 x 1900 mm |

|

kW Motor power 7.5 kW |

|

Brush version mm Brush version station 2 + 3: |

|

1x brush unit with 4x disc brush Ø 255 mm |

|

Oscillating system, brushes rotating crosswise |

|

Equipped with automatic workpiece height compensation |

|

Brush version station 4 + 5: |

|

2x round brush Ø 350 mm |

|

Oscillating system, brushes rotating left and right |

|

Equipped with automatic brush height compensation |

|

Brush power kW 6x 2.2 kW motors with frequency control |

|

Press rollers Heavy duty press rollers; rubber with a oil and heat resistant coating |

|

Electrical specifications |

|

Input Voltage V 400 V |

|

Frequency Hz 50 Hz |

|

Input Current A 32 A |

|

Connected Load kW 16 kW |

|

400V plug A 32 A |

Suitable for applying a 2 mm radius to metal sheets up to 600 mm wide

Super Edge Rounder

The SER600 is the longest machine in the Q-Fin range. This deburring and grinding machine is equipped with 5 processing stations: a grinding unit (1st station) followed by 4 oscillating brushes (stations 2+3) and 2 round brushes (stations 4+5). You can use this machine to apply a large rounding (R2) to your metal cutting parts. The Super Edge Rounder is suitable for flat sheet metal parts from 4 to 40 mm thick and up to 600 mm wide. The ideal machine for finishing sheet metal parts to be powder coated or galvanised.

The SER600 has been specially developed by Q-Fin to provide flat sheets up to 600 mm wide with a 2 mm radius.

Suitable for

Line grain finish

Slag removal

Deburring

Oxide layer removal

Edge rounding

Grinding

Roughness grinding

– Conveyor belt speed adjustable: 0.3 – 8 m1/min

– With magnetic support for ferrous product fixation

– 1x grinding unit + 4x disc brush + 2x round brush

– Minimum workpiece dimensions: 50 x 50 mm (ferrous)

– Maximum workpiece width: 600 mm

– Maximum workpiece height: 40 mm

– Power consumption of machine: 400 V, 50 Hz, 32 A, 16 kW

– Dimensions: 3640 x 1585 x 2085 mm (L x W x H)

3.560 KG