Description

RASI S80.3-U – Year 2008

1 pc: used CNC tube bending machine – fully automatic, electro-hydraulic right-bending CNC mandrel bending machine

Make RASI

Model S80.3-U

Year of construction: 2008

Operating hours: Only approx. 180 hours – was not used due to software problems with the existing 3R solutions CAD system

electr. Connection: 400 V, nominal current. 9 A

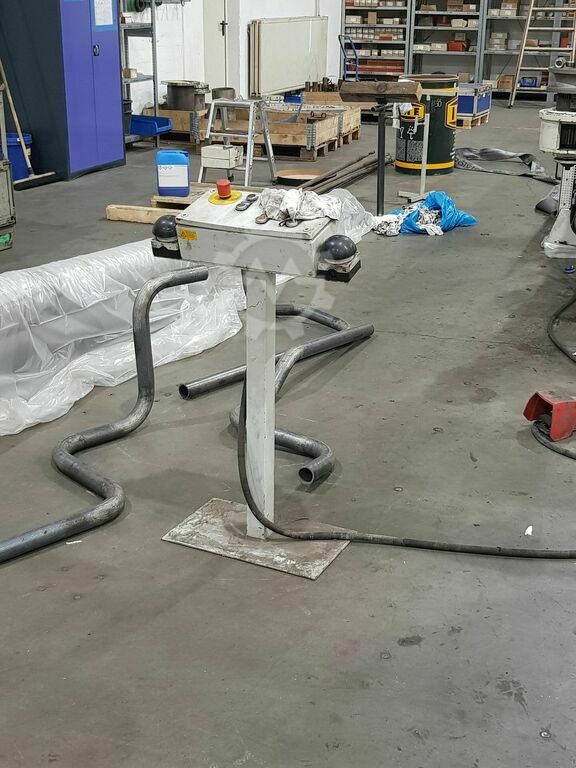

separate operation panel

Sale ex location free loaded truck

Purchase price + VAT

including invoice

Details:

Fully automatic, electro-hydraulic right-bending CNC mandrel bending machine Rasi S80.3-U

For pipes up to D 80 (steel) or D 76.1 (VA) (right-bending without cross-pieces) with S80 bending head

Modern industrial PC control, proportional hydraulic control from Bosch Rexroth, with up to 4 proportional axes (up to 12 measuring axes can be expanded), expandable for free-form bending.

The modular structure offers the customer many interesting expansion combinations and selection options such as: with the Auromess new Right from the first pipe! – world first.

With the intelligent pipe measuring system Aura Mess (patent pending) it is possible to manufacture precisely fitting bent parts even with unknown pipe behavior without sample material.

with the free-form bending device K1 or K2 for roller, ring and curve bending, 3-D bending and twisting directly on the bending head up to D 48.3

With the automatic tool changer W2 (cross table) for mandrel bending also with multiple grooves up to D 48.3 with dome or 60×6 (mandrelless) – multi-stage tools with mold jaws up to D 48.3 with mandrel or 60×5 (mandrelless)

– the autom. Change from mandrel to roll and free-form bending up to OD 42.4

– the automat. Change of the bending direction from right to left bending and vice versa also

within a bending part (with W3)!

– with the use of the cross table fixation W2f for pipes up to max. D 60 x4 (mandrel bending)

with the possibility of autom. Change of bending direction W3 from right-bending to left-bending

and vice versa, for pipes up to D 42.4x 2.0 (VA) or for pipes up to D 38 x 2.0 (VA) also within a bent part and within one clamping. This greatly increases the freedom of bending.

with the addition of the 9-roll bending machine UNI80 for tubes up to D 88.9×5.0 opt. 100x 4

80 the proportional hydraulics, the PC control, the feed and plane rotation system of the mandrel bender are consistently used for fully automatic path-controlled ring and curve bending, both left and right bending.

Basic mandrel bending machine S80

– Incl. Basic frame SR-GS. Arrangement of the hydraulics below the machine body.

– Incl. Bending device carrier BT80

– Incl. Proportional hydraulic SR-HY 11 kW with PC control

– Incl. Bending head S80 with bending cylinder D140 – S80

– Incl. 1 hydr. Tool return with hydr. engine

– Incl. hydr. Actuated mandrel support

– Incl. Isometric and railing software

– Extension of the bending device carrier to 6 m (starting from 3 m)

– Version with plug-in flexible shaft

– Clamping adapter L = 100mm for bending tools type A to Rm 90

– Clamping adapter for pipes D4 – D22

– Approach adapter A for slide rails up to RM 90 required.

– Hydraulically operated moving slide rail device

Tube feed and level rotation system

– V3 fully automatic pipe feed with automat. Rotating unit

– Type C chucks for D4 to D82 for item V3 Automatic tube feed with automatic rotating unit

– Lamella collet with stop and funnel D10 -D19

– Lamella collet with stop and funnel D19 -D28

– Lamella collet with stop and funnel D28 -D37

– Lamella collet with stop and funnel D37 -D46

– Lamella collet with stop and funnel D46 -D55

Software and hardware accessories

The RASI programming station software runs on PCs with the Windows 95, -98, -2000, -NT or Windows XP operating system,

– CAD connection via xyz-ASCII file

Accessories for mandrel bending

– mandrel lubrication device

– Anti-wrinkle holder

– 7 mandrel bars

– Slide rails for pipe diameters 12, 16, 18, 20, 21.3, 25, 26.9, 28, 30, 33.7, 35, 38, 42.4, 48.3,

44.5, 54, 57, 60.3, 76.1 mm are available.

Safety devices required for automatic bending operation

– Double light barrier side length max. 6 m

Further accessories for mandrel bending

– Bending arm support for extreme bending tasks

Separate bending machine UNI 80 that uses the existing hydraulics and control of the mandrel bending machine

Bending machine UNI 80 for S coupling without its own hydraulic system

Incl. Base frame UNI80-GS, mobile and rotatable

Incl. Bending table UNI 80-BT2 with a bending force of 36t

Incl. Preparation F separate mandrel bending unit of the S-Class

Ring bending accessories

– Radius knife bar width 225 mm (analog)

– Case hardened roller set for 2 “D 60.3

– Case-hardened roller set for 3 “D 88.9 (3 shafts W112 necessary)

Tools for segment bending and straightening

– 2 cast counterholders with bolts for ¾ “to 3”

Coupling module from mandrel bender with ring bender

– Manual switching valves from mandrel to ring bending

The sale takes place under exclusion of any guarantee.