Description

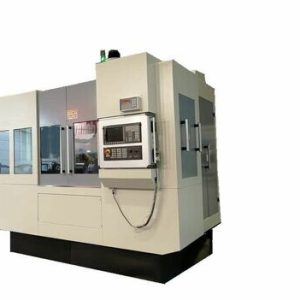

Reishauer RG-500 CNC Thread & Worm Grinding Machine – Year 2014

Specifications:

Grinding Spindle Speed: Up to 10,000 RPM

Workpiece Diameter: Up to 300 mm

Workpiece Length: Up to 1000 mm

CNC Control System: Fanuc, Siemens, or equivalent

Machine Weight: 6000 kg

Dimensions: 3500 mm x 2500 mm x 2000 mm

Tool Capacity: 10 tools

Coolant System: Integrated advanced cooling system

Applications:

The REISHAUER RG500 Grinding Machine is ideal for:

High-precision cylindrical and surface grinding

Profile grinding for complex shapes and geometries

Finishing operations requiring exceptional surface quality

Manufacturing of components for automotive, aerospace, and precision engineering industries

With its advanced capabilities and robust design, the REISHAUER RG500 Grinding Machine stands out as a reliable solution for a wide range of grinding tasks, providing consistent quality and productivity for industrial applications.

The REISHAUER RG500 Grinding Machine is a versatile, high-performance grinding machine designed to meet the needs of both small and large-scale industrial operations. Known for its precision and reliability, the RG500 excels in various grinding applications, including cylindrical, surface, and profile grinding. This machine is engineered to deliver consistent, high-quality finishes while ensuring efficient and user-friendly operation.

Key Features:

Precision Grinding:

Provides high-precision grinding with tolerances as tight as ±0.001 mm, making it ideal for applications requiring fine finishes and accurate dimensions.

Offers exceptional surface quality, suitable for components that demand intricate detailing.

Robust Construction:

Built with a heavy-duty cast iron frame that minimizes vibration and enhances stability during the grinding process.

Designed for durability and longevity, capable of withstanding continuous operation in demanding environments.

Advanced Control System:

Features a sophisticated CNC control system for precise management of grinding operations.

Includes an intuitive interface with easy-to-use software for programming, monitoring, and adjusting grinding parameters.

High-Speed Grinding Spindle:

Equipped with a powerful grinding spindle that can reach speeds of up to 10,000 RPM.

The spindle motor provides consistent torque, ensuring smooth and efficient material removal.

Versatile Applications:

Capable of performing a wide range of grinding tasks, including cylindrical, surface, and profile grinding.

Suitable for various materials, including metals, alloys, and composites.

Automated Features:

Incorporates automatic tool changers and dressing systems that reduce setup times and increase productivity.

Equipped with automated loading and unloading systems for improved workflow efficiency.

User-Friendly Design:

Ergonomically designed for easy access to the work area and controls, enhancing operator comfort and productivity.

The control panel provides clear visual feedback and real-time status updates.

Efficient Cooling System:

Features an advanced cooling system that maintains optimal operating temperatures, reducing thermal deformation and ensuring consistent grinding accuracy.

The cooling system helps prolong tool life and improves the quality of the finished workpiece.

Safety and Environmental Compliance:

Equipped with safety features such as automatic shutdown in the event of anomalies, protecting both the machine and the operator.

Designed to comply with environmental regulations, minimizing emissions and energy consumption.

Maintenance and Serviceability:

Engineered for easy maintenance with accessible components and simplified service procedures.

Includes diagnostic tools and support for remote monitoring to facilitate troubleshooting and minimize downtime.