Description

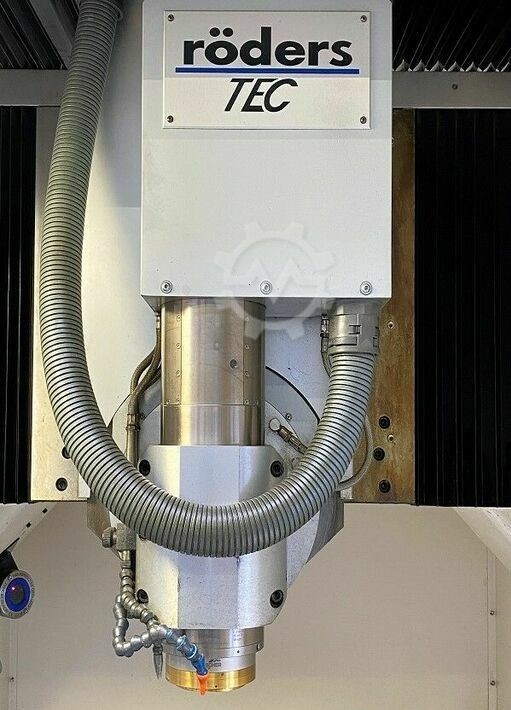

RÖDERS| RFM 1000S/2 with table 3R

Vertical machining center with 4th axis

Only used for finishing in steel.

year of construction: 2003

Control: RÖDERS HSC-control RMS6

working area: 1.000 mm x 800 mm x 600 mm

machine table: 1.200 mm x 1.000 mm

Workpiece mass: maximum 2.000 kg

Axis drive: AC synchronous motors

feeds: 0 – 30.000 mm/min

Dimensions with control cabinet (WxLxH): 3,250 mm x 3,550 x 3,600 mm

Weight: approx. 13,200 kg

Equipment:

Vector-controlled high-frequency milling spindle, make: FISCHER MFW1412/36

(100-36,000 rpm, 17 kW, HSK 50 interface, maximum tool Ø 20 mm)

NC precision swivel axis, swivel range: -3 to +45 degrees

Tool changer 18-fold

Tool measuring laser built into the tool changer

Minimum quantity lubrication

Workpiece cleaning

Milling tool cleaning

Fan for temperature stabilization of the machine frame

Sealing

Cabin completely closed

Country module German (D, A, CH)

Simultation RMSCut with cut-out function

RÖDERS Job Management RJM

Remote maintenance with ISDN

Network connection 100 mBit/s RJ45

3D probe automatic HSK50 RFM1000(S)/2

RÖDERS Inspect

Machine manuals, German