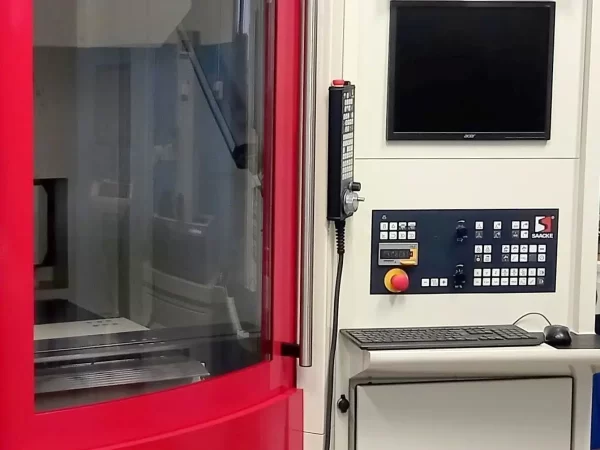

SAACKE UW I D CNC 5 Axis Tool Grinding Machine – Year 2020

Contact us for price

Description

SAACKE UW I D – Year 2020

CNC 5 Axis Tool Grinding Machine

Technical specifications of the SAACKE UW I D CNC grinding machine

number of numerically controlled axes: 5 (X, Y, Z, A, B)

working area (l x w): 3000 x 2100 mm

feed rate in the X/Y/Z axis: 625/305/305 mm

horizontal rotation range of grinding head: 245°

speed of feeds in the X,Y,Z axis: 0-15 m/min

grinding head turning speed: 120°/s

maximum tool length (in claws): 480 mm

maximum tool length (from front edge of headstock): 430 mm

maximum tool diameter: 250 mm

number of stations in rotary grinding wheel magazine: 6 pcs.

maximum grinding wheel diameter: 150 mm

maximum spindle speed (A axis): 600 rpm

spindle cross-section (A-axis): fi 32 mm

spindle indexing accuracy (A axis): ± 15

spindle power (A axis): 3 kW

minimum grinding electro-spindle speed (B axis): 2000 rpm

maximum grinding electro-spindle speed (B axis): 10000 rpm

power of grinding electro-spindle (B axis): 16 kW

position measuring system (B axis): intermediate system

height of claws: 195 mm

accuracy: 0,0001 mm

useful table surface for tailstocks and telescopes: 900 x 185 mm

X axis drive power: 3 kW

grinding head drive power (Y axis): 3 kW

power of cross slide (Z axis): 3 kW

grinding head rotation power (B axis): 3 kW

power supply: 3x 400 V; 50 Hz

weight of machine UW I D: approx. 4900 kg

Equipment of the CNC grinding machine

CNC controller: NUM Flexium Plus

software extension with additional functions

measuring probe: RENISHAW 3D

glass measuring rulers: HEIDENHAIN

automatic grinding wheel changing system

liquid-cooled grinding electro-spindle

digital servo drives: NUM

hydraulic chuck: SCHUNK

PC unit

spindle taper: ISO 50

workspace illumination

grinding disc mounting flange with automatic quick-action clamping: HSK-E50

collet M24 for DIN 69871 shank taper

union nut for clamping reduction sleeves

control cabinet with cooling unit

SAACKE UW I D CNC universal grinding machine was manufactured in Germany in 2020. The extremely powerful machine is designed for the fully automated wet grinding process of a wide range of tools, such as knives, cutters or drills, using grinding discs with a maximum diameter of 250 mm and a length of 480 mm.

Precision machining of workpieces is performed in five numerically controlled axes (X, Y, Z, A, B) in a fully illuminated workspace of the machine with dimensions (L x W) 3000 mm x 2100 mm, located behind a circular sliding door with polycarbonate glass panels. The X,Y,Z axes are seated on sturdy guideways with hardened tracks, and are driven by high-precision twin-nut-pull screws.

The high-tech SAACKE UW I D CNC grinding center significantly increases production efficiency, saves time and reduces costs. It is achieved through the possibility of using a chain or pallet system for automatic tool feeding and processing the workpieces within it in a single production cycle. The storage area, which is separate from the workspace with an automatic grinding wheel changing system, can accommodate up to six grinding wheels with a maximum diameter of 150 mm each.

The SAACKE UWID CNC tool and cutter grinding machine has a wide range of equipment, including a RENISHAW 3D measuring probe for automatic tool positioning and transfer of geometric data to the software, a NUM Flexium Plus CNC control extended with many additional functions and HEIDENHAIN glass measuring rulers. The total weight of the grinder is approximately 4900 kg.