CORMAK MILL 500 Eco Line – 2020 Model

Contact us for price

Description

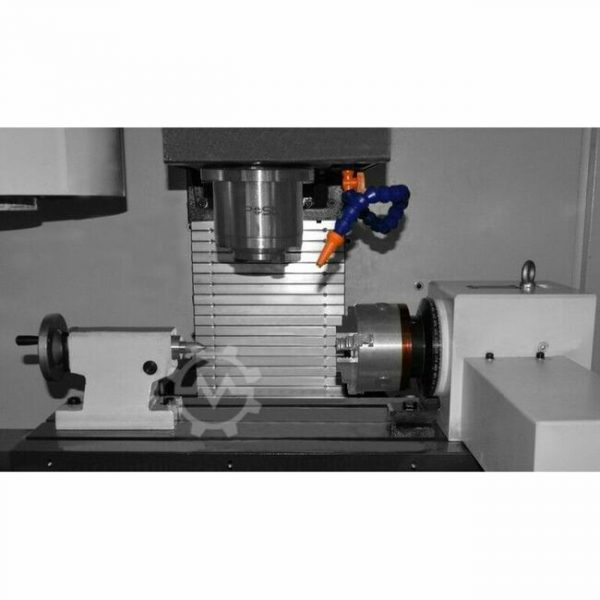

MILL500 CNC machining centres are equipped with a 4th axis on the basis of verified components, ensuring long-term reliability. The solid body of the machine makes sure that machining is efficient and precise. Hermetic chamber provides security and clean working environment. The table with tempered surface can carry workpieces without burdening mechanical elements of the construction. Every device of this series is equipped with an efficient cooling system, providing optimal machining conditions.

4th axis by default in the set.

Technical data:

– Table dimensions: 800×260 [mm]

– Spindle taper: BT30 (BT40 optional)

– X-axis travel: 450 [mm]

– Y-axis travel: 320 [mm]

– Z-axis travel: 420 [mm]

– Spindle taper from table surface distance: 90–470 [mm]

– Quick travels: 10/10/8 [m/min]

– X/Y/Z axes servomotor torque: 6/6/7.7 Nm

– Positioning accuracy: ±0.02 [mm]

– Positioning repeatability accuracy: ±0.01 [mm]

– Spindle speed: 8000 [rpm]

– Motor power: 3.7 kW

– Control system: SINUMERIK 808D

– Weight: 2100 [kg]

– Dimensions: 2100×1800×2200 [mm]

Available equipment

– SIEMENS 808D

– 4th axis

– Manual chuck

– Tailstock

– SIEMENS servomotors

– 8000 [rpm] spindle speed range

– 10-tool magazine

– 3-colour alarm indicators

– Lighting

– Hermetic body of the machine

– Automatic lubrication system

– Pneumatic system

Optional equipment:

– Siemens 828 / FANUC control systems

– Spindle range of 10000 / 12000 [rpm]

– Cooling via spindle

– Belt shavings ejector + container

CORMAK MILL 500 Eco Line – 2020 Model