Description

SCM morbidelli cx100 CNC Drilling Center – Year 2021

Drilling, Grooving & Vertcial Routing machine

| Workpiece max. dimensions | mm | 3050x900x60 | ||

| Workpiece min. dimensions | mm | 200x70x10 | ||

| X-Y axes speed | m/min | 40 | ||

| Independent vertical spindles | n. | 12 | ||

| Independent horizontal spindles X direction | n. | 4 | ||

| Independent horizontal spindles Y direction | n. | 2 | ||

| Electrospindle motor power | kW | 5,5 | ||

Drilling, Grooving & Vertcial Routing machine. The drilling machine that carries out all drilling operations, grooving and vertical routing. Very high productivity guaranteed, no operator’s intervention for the worktable tooling.

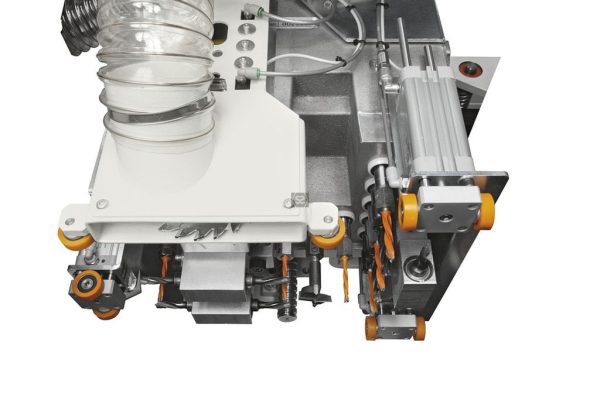

F18L RO.AX Drilling Head

12 x Vertcial Drilling Heads

3 x Horizontal Drilling Heads with double outlet

2 x Along X Direction

1 x Along Y Direction

Device to increase drilling pressure along z axis

4.5Kw Electro spindle with rapid manual tool change

Console with ‘Eye-M’ integrated PC

Remote machine control

Maestro Active Software

PERFECT FINISH: DRILLING FROM THE TOP

Drilling from the top allows to use the outside of the panel as a reference concealing defects; the result is to always move any difference in thickness to the inside of the cabinet.

PERFECT JOINTS: AUTOMATIC READING OF THE WORK PIECE LENGTH

Any discrepancy between the actual length of the panel and the one set is corrected by a precision reading laser allowing for perfect alignment.

EASY AND INTUITIVE: MAESTRO SOFTWARE

CAD/CAM software designed and developed entirely by SCM in Windows environment that allows to program easily any element to be realized.

It provides the customer with all the tools necessary for the design, the management of the tools and related processes. Full Details on request. In excellent condition.