Description

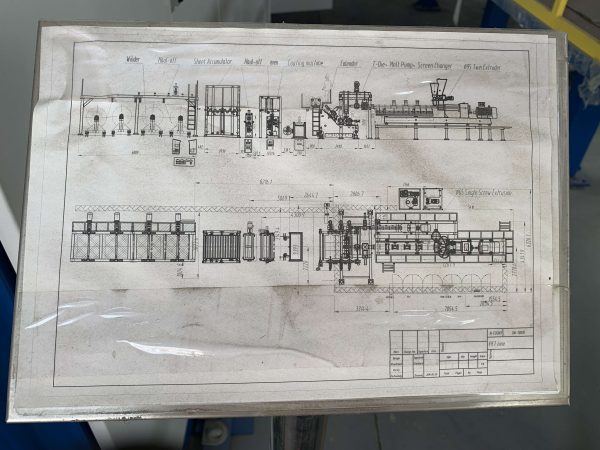

Shanghai Jobbetter Plastic Machinery Future Tech UW95/44 – Year 2023

Twin Screw PET / PP / PS Extrusion Line UW95/44

Make: Future Tech

Model: Twin Screw PET / PP / PS Extrusion Line

Condition: Excellent – new after testing.

Availability: Immediately

Materials: PET / PP / PS (Virgin and Recycled Flake)

Material Width Range: 0.18mm – 1,2mm

Max Sheet Width: 1100mm

Output: 1000kg/hour

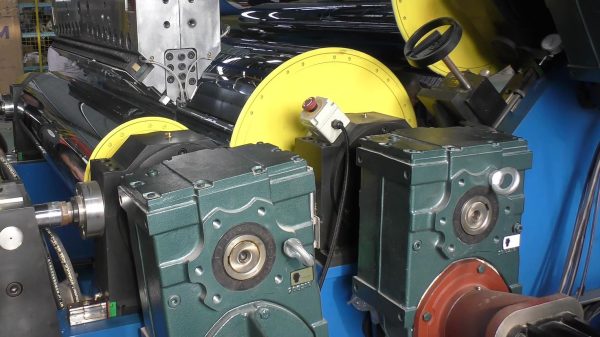

Main Extruder: 95mm Future Tech UV95 twin screw extruder water cooled

Co-Extruder: 65mm Future tech single screw with 30kW ac motor & invertor

Running from 0.18mm to 1.2mm thick PET up to 1000kg/hr.

Mix of virgin, post consumer bottle flake and skeletal flake.

2 Component volumetric blending system for primary and secondary extruders.

95mm Future Tech UW95/44 twin screw extruder water cooled.

250kW ac motor with inverter drive.

Triple vented with liquid ring vacuum pump system.

Hydraulic screen changer, dual piston, filter dia Φ180mm, manual control.

JCTimes model 275 gear pump with ac motor and PLC control.

65mm Future Tech single screw co extruder with 30kW ac motor and invertor.

Vented with liquid ring vacuum pump system. Manual screen changer. JCTimes model melt pump

with ac motor and invertor speed control.

A-B-A, A-B, B (A=10-15%, B=85-90%) feed block with selector plug.

1230mm wide flex lip single manifold sheet die.

Max net width of the sheet is 1100mm.

Manual T- die. Flex bottom lip. Fixed uper lip. Close approach.

1400mm wide 3 roll polishing stack with horizontal configuration ( 350mm x 650mm x

650mm diameter). Individual servo speed drives. 3 zone pump group.

1100mm wide silicon coater device and dryer. 4 rolls 200mm diameter.

1100mm wide cantelever winding system with accumulator. 4 position. 3″ and 6″cores.

Max roll weight 1200kgs. Max roll diameter 1000mm.

Payment Terms: 20% with order and full balance before loading.