Description

Studer S40 – CNC Grinder Machine

ID & OD grinding

TECHNICAL DETAILS

– number of axes : 4

– distance between centers : 1000 [mm]

– center height : 175 [mm]

– travels (Z/X) : 1.050 x 275 [mm]

– feeds max (Z/X) : 10 / 5 [m/min]

WHEELHEAD

– universal type : 2 external wheels (left & right),

1 internal

– external wheel dimensions : 400 x 80 x 127 [mm]

– motor power : 7,5 [kW]

– speeds : 1.670 – 2.110 [rpm]

– swivelling range : -15 to +225 [°]

– B-axis indexing precision : 0,001 [°]

WORKPIECEHEAD

– cone : SA50

– speeds : 1 – 1.027 [rpm]

– power : 0,8 [kW]

TAILSTOCK

– cone : CM3

– quill stroke : 35 [mm]

DIMENSIONS

– floor space : 3.700 x 2.300 [mm]

– height : 2.200 [mm]

– weight : 7.000 [kg]

HOURS

– under power : 48.941 [h]

EQUIPMENT

– CNC FANUC 16 TB

– options Release B, Quick-Set, STForm & Pictogramming

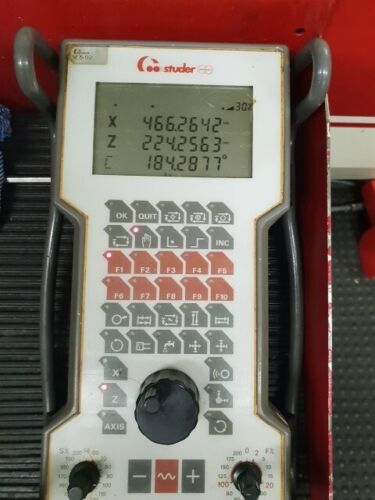

– electronic deported handwheel

– 3 colors staus lamp

– 1 FISCHER MFV1275 electrospindle for ID

75.000 [rpm]

– fine B-axis for wheelhead indexing

– C-axis for workpiece indexing

– tailstock with fine adjustment of concentricity

– electronic contact detection device : Sensitron

– micrometric table swivelling adjustment : 8,5 [°]

– MOVOMATIC C65 autocalibration device with length probe

– HEIDENHAIN linear scales upon X/Z

– dressing device upon table

– dressing device upon workpiecehead

– dressing device upon tailstock

– air cushion lift-off for workpiecehead and tailstock

– cooling unit for wheel’s motor

– pneumatic clamping pot with collet chuck

– mist extractor : ERNI SC610/D