Description

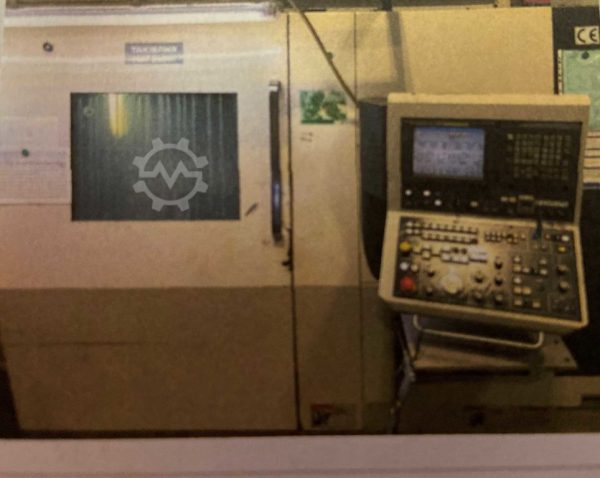

TAKISAWA TMM 250 M1 – Year 2009

CNC lathe / turning and milling centre with driven tools, Y-axis and Fanuc 180is-T control.

This machine has 2 spindles and 2 revolvers. It is able to work with both turrets on one spindle (4 axes).

Equipment:

32 bit Fanuc CNC control with Manuel Guide i, and internet interface.

10.4 inch colour screen

AC digital Fanuc spindle and axis motor

2 VDi 40 turrets with 15 tool places each

double holders are possible ᐳ therefore up to 60 tool places

max. 15 driven WKZ per turret possible

Y-axis 100mm (+/- 50mm) Flat guided in upper turret

Drive power left: 15/22 kW, max. torque 433 Nm,

Speed 4000 rpm

bar passage left: 76 mm

Drive power right: 15/22kW, max. torque 433Nm, max.

strain rate 4000 rpm

bar passage right: 51mm

Drive power of the driven tools: 3.7kW/5.5kW

Speed of the driven tools: max. 4000 rpm

Torque: max 33Nm

tap without length compensation

distance between spindle lugs : 1130mm

Blow out the spindle by M command

Coolant system 4bar

High pressure coolant pump 9bar

cooler for regulating the coolant

Foot switch for both chucks

autom. central lubrication

Tool monitoring system (Raku Raku)

automatic switch-off

Linear measuring system

Measuring arm for tool measurement

Accessories:

Driven tools X: 15 pieces

Driven tools Z: 15 pieces

collet holder: 15 pieces