Description

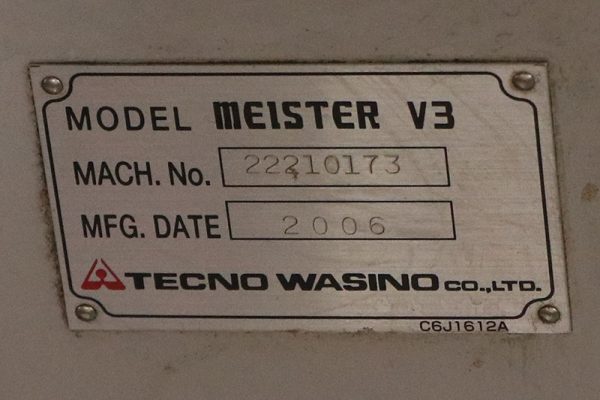

TECHO WASINO MEISTER V3 Surface Grinder – Year 2006

CNC SURFACE GRINDER, CNC GRINDING & D

Amada MEISTER V3 CNC

Y.O.M.: 2006,

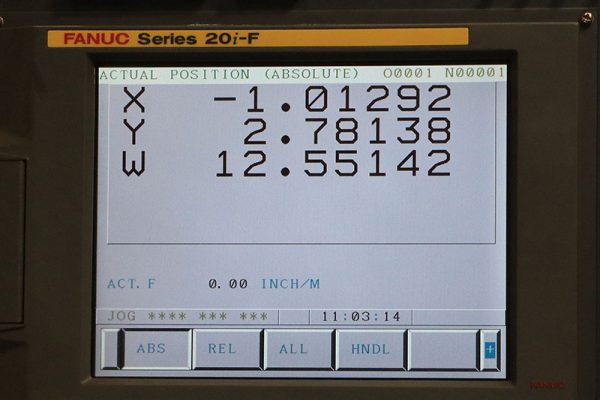

FANUC 20i-F

6″ x 14″ Amada Meister V3 “CNC”

“MADE IN JAPAN”

“HIGH PRECISION – HIGH PRODUCTIVITY”

SURFACE & PROFILE GRINDER

S/N: 22210173 NEW: 2006

SPECIFICATIONS:

TABLE WORKING SURFACE ……. 17.7″ x 5.9″

MAX. LONGITUDINAL TRAVEL …. 19.6″

MAX. CROSS TRAVEL ……….. 7.8″

SPINDLE CENTER TO TABLE ….. 15.7″

LONGITUDINAL TABLE SPEED …. 3′ – 131′ FPM

MAX. No. OF TABLE

MRECIPROCATIONS WITH

0.591″ STROKE ………….. 250

CROSS/SADDLE FEED:

RAPID CROSS FEED, JOG (3)…. 0 – 1312FT./MIN.

1,640 FT./MIN.

3,280 FT.MIN.

HANDLE FEED, PER REV. …… 0.0004″, 0.004″,

0.04″, 0.15″

HANDLE FEED,PER GRAD. …… 0.000004″, 0.00004″,

0.0004″, 0.0015″

MINIMUM FEED INCREMENT …… 0.0000010″

POSITION DETECTION SYSTEM … GLASS SCALE/0.05um

WHEELHEAD:

RAPID WHEELHEAD FEED (JOG) .. 3.9″/MIN. & 39″/MIN.

HANDLE FEED, PRE REV. …… 0.0004″, 0.004″,

0.04″, 0.15″

HANDLE FEED,PER GRAD. ……. 0.000004″, 0.00004″,

0.0004″, 0.0015″

MINIMUM FEED INCREMENT …… 0.0000010″

POSITION DETECTION SYSTEM … LINEAR SCALE/0.05um

WHEEL SPINDLE:

SIZE (OD x WIDTH x BORE) …. 8″ x 1/4″ x 1- 1/4″

WHEEL SPINDLE SPEED,

INF. VAR. …………….. 500 – 5,000 RPM

MOTOR ………………….. 3 H.P.

FLOOR SPACE …………….. 74″ x 58″ x 74″H

APPROX. MACHINE WEIGHT …… 4,840 LBS.

MACHINE FEATURES:

FANUC 20i-F CNC

– SIMULTANEOUS 2-AXIS + 1 AXIS

– COLOR CRT GRAPHIC DISPLAY

– AXES DISPLAYED, X, Y & W

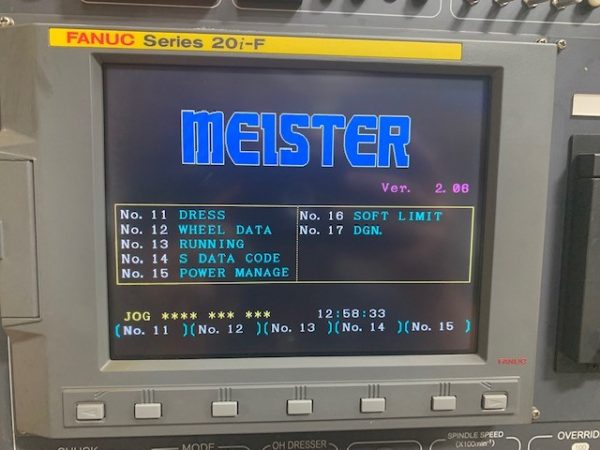

– EASY TO USE CONVERSATIONAL SOFTWARE

– (1) MULTI WORK GRINDING

(2) SURFACE GRINDING

(3) SLOT GRINDING

(4) PATTERN GRINDING

(5) CONTOURING GRIND

(6) PATTERN C.

(7) PROFILE DRESSING

(8) PATTERN D.

(9) R. TAPER

(10) SETTING

– FULL KEYPAD WITH G-CODE PROGRAMMING

– ORIGINAL SOFTWARE (MEISTER VERSI0N 2.06)

ALLOWS OPERATOR TO BE PRODUCTIVE

WITHOUT HAVING TO KNOW COMPLEX

CNC PROGRAMMING.

– PATTERN GRINDING COMPLEX SHAPES CAN BE

PROCESSED EASILY BY COMBINING FIVE PATTERNS.

THE COMBINATION OF PLUNGE AND TRAVERSE

OPTIONS MAKES SELECTING THE APPROPRIATE

PROCESSING EASY.

– CONTOUR GRINDING CAN BE IMPLEMENTED BY

INPUTTING THE GRAPHIC DATA OF ARBITRARY

SHAPES. ROUGH GRINDING BY PLUNGE

GRINDING CAN ALSO BE IMPLEMENTED,

AND THE CREATED DATA CAN BE SAVED

IN THE CNC AREA.

– PATTERN DRESSING BY INPUTTING THE DIMENSIONS

REQUIRED FOR THE BASIC SHAPE ON THE SCREEN,

THE GRINDSTONES PERFORM THE MOLDING USING

A SIMPLE PROFILE DRESSER. THE GRINDSTONES

CAN ALSO PERFORM THE MOLDING DURING THE

PROCESSING AND INTERRUPT DRESSING.

– HIGH SPEED TABLE RECIPROCATION, AMADA WASINO’s

PROPRIETARY POSITIONING SCALE AND HYDRAULIC SERVO

SYSTEM CAN ACHIEVE 250 TABLE REVERSALS PER MINUTE,

A SIGNIFICANT INCREASE IN GRINDING EFFICIENCY.

– TABLE FEATURES “V-FLAT” SLIDEWAYS WITH HOLLOW

RUNNERS FOR HIGH SPEED AND ACCURACY. MEISTER

SERIES GRINDERS SUPPORT RECIPROCATION SPEEDS

TWO TO THREE TIMES FASTER THAN ANY FORMER

MODEL, GREATLY IMPROVING EFFICIENCY.

– FANUC AC SERVO DRIVES

– HANDWHEELS FOR TABLE & SADDLE MOVEMENTS,

CROSS FEED HANDWHEEL IS ELECTRONIC,

MANUAL PULSE GENERATOR MOUNTED ON RIGHT

OF TABLE AT ERGONIC HEIGHT, FOR EASE

OF OPERATION.

EQUIPPED WITH:

6″ X 13.78″ ELECTRO-PERMANENT MAGNETIC CHUCK,

MADE BY “KANETEC” IN JAPAN FOR AMADA WASINO,

WITH VERY LOW HEAT EMITTED, PERMITS FINER,

SMALLER WORKPIECES TO BE HELD WITHOUT

HEAT DISTORTION.

VARIABLE HOLD NEUTROFIER CONTROL

3-DRESSER ARRAY MOUNTED ON TABLE,

TO THE LEFT OF THE CHUCK

“FUJI” COMBINATION DUST COLLECTOR & COOLANT SYSTEM,

WITH PAPER FILTRATION

“DAIKO OIL COOLING UNIT, USES DTE 22 Oil

FACTORY INSTALLED STAINLESS STEEL GUARIDNG IN

GRINDING POCKET.

WORK LIGHT

LEVELLING BLOCKS

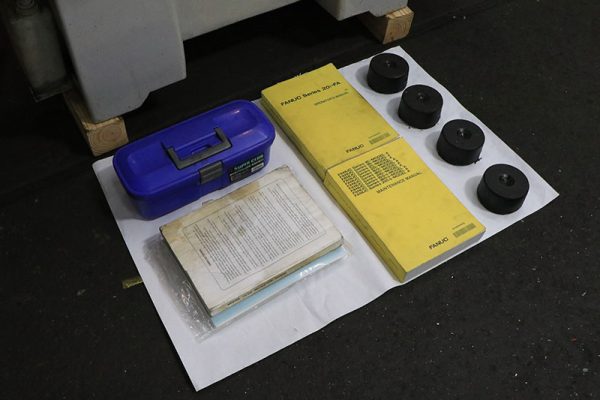

ORIGINAL TOOL KIT

SET OF MANUALS

3 HP AC MOTOR WITH INVERTER DRIVE, PROVIDING

INFINITLEY VARIABLE SPINDLE SPEEDS

MACHINE IS WIRED FOR 3/60/208 VOLTS

SUPERIOR CONDITION FROM A SMALL SHOP – OWNER RETIRED

ORIGINAL PAINT – EXCEPTIONAL APPEARANCE

RUNS BEAUTIFULLY!

INSPECT UNDER POWER I