Description

TOYODA FH500J CNC Horizontal Machining Center – Year 2018

Specifications:

TRAVELS

-X AXIS: 28.7″

-Y AXIS: 28.7″

-Z AXIS: 33.4″

PALLET SIZE: 500MM / 19.68″ X 19.68″

PALLET INDEX: FULL 4TH

NUMBER OF PALLETS: 2

PALLET HEIGHT FROM FLOOR: 43.3″

APC CHANGE TIME: 9.5 SEC

TABLE INDEXING TIME: 2.3 SEC

MAX WORKPIECE RANGE: 31.5″ X 39.37″

MAX WORKPIECE HEIGHT: 29.3″

MAX TABLE LOAD: 880 LBS

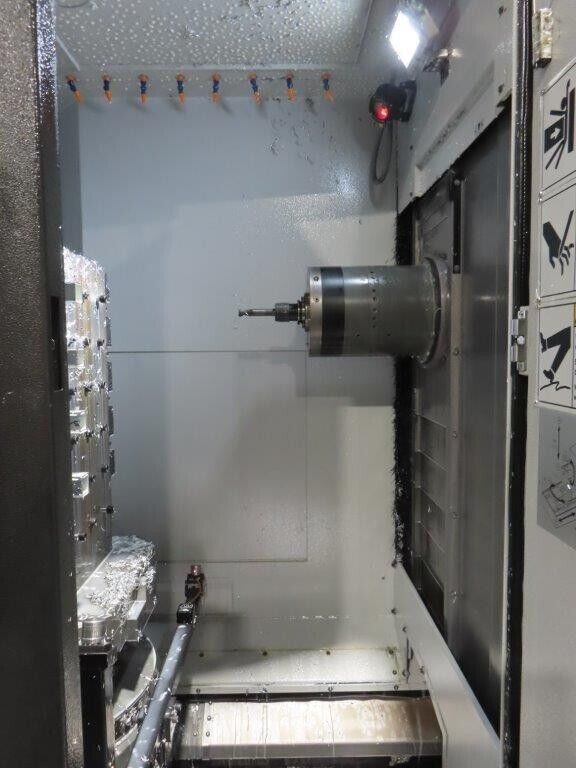

SPINDLE SPEED: 15,000 RPM / DIRECT DRIVE / DUAL CONTACT

SPINDLE TAPER: CAT- 40 / BIG PLUS

MAIN MOTOR: 30 HP

SPINDLE NOSE TO TABLE CENTER: 3.93″ – 37.4″

SPINDLE CENTER TO TOP OF PALLET: 1.97″ – 30.7″

TOOL STORAGE: 120

TOOL CHANGE TIME: 2.6 SEC CHIP TO CHIP / 1. T-9

TOTAL FLOOR SPACE REQ: 92″ X 183″ X 112″

MACHINE WEIGHT: 29,700 LBS

POWER: 220V / 3 PHASE / 50KVA

Equipped With:

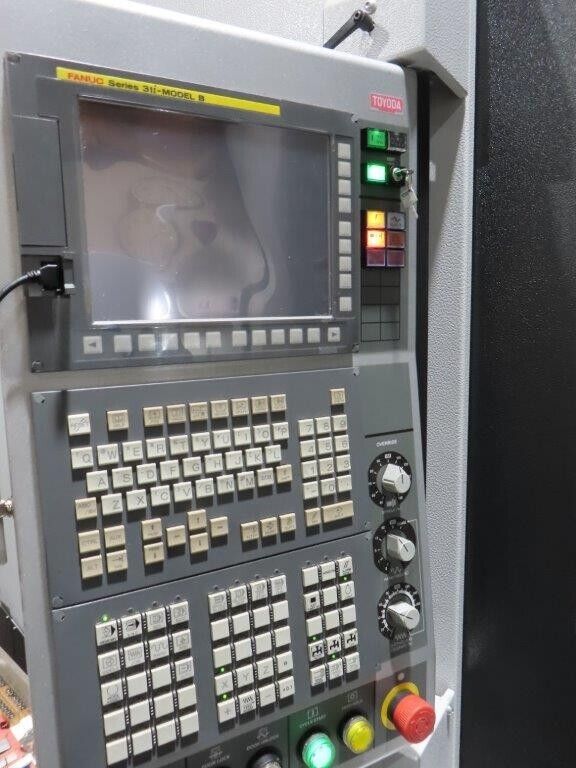

FANUC 31I MODEL B

200 TOOL OFFSETS

OVERHEAD COOLANT SHOWER

HAND HELD SPLASH GUNB AT APC LOAD STATION

(1) GIG DATA SERVER

WORKPIECE COORDINATE SYSTEM – 300 SETS

PART PROGRAM STORAGE 8192KB (20480M) / 1000 REGISTERABLE PROGRAMS

CHIP BLASTER JV-40 HIGH PRESSURE AUTO VARIABLE VOLUME CTS AT 1000 PSI, 10.5 GPM, 100 GALLAN TANK, SINGLE BAG FILTRATION.

FULL 4TH ROTARY

CHIP CONVEYOR / RIGID TAPPING / SPINDLE CHILLER

RENISHAW SPINDLE PROBE PACKAGE OMP400

RENISHAW LASER TOOL PROBE PACKAGE NC-4 BROKEN TOOL DETECTION

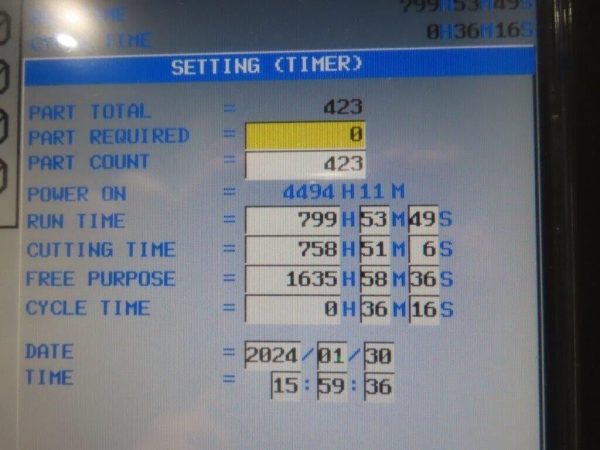

HOURS : POWER ON: 4494 / RUN: 799 / CUTTING: 758