Description

Working area: 3000 x 1500 x 115 mm

Control: Siemens Sinumerik 840D

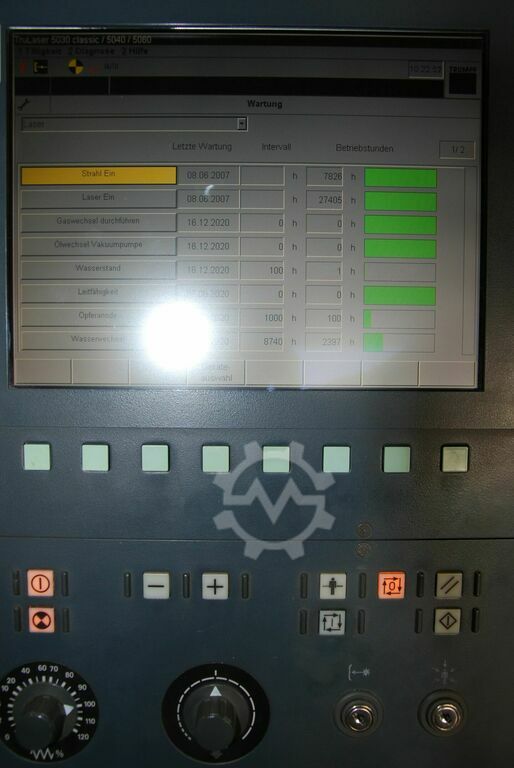

Effective laser cutting capacity: 7826 hrs.

Max. sheet thickness steel 25 mm

Max. sheet thickness stainless steel 25 mm

Max. sheet thickness aluminum 15 mm

Machine has been fully serviced by TRUMPF.

Last maintenance September 2020.

Standard equipment:

laser unit: CO2 laser TruFlow 6000 high frequency controlled,

maintenance-free turbo radial blower, cooling unit, logbook function

automatical pallet changer

drives: gantry drive in combination with linear direct drives

cutting head quick change device

4 laser cutting heads: 3.75″ lens, 5″ lens, 7.5″ lens, 10″ lens

cutting gas pressure adjustment programmable

ControlLine capacitive height control and process control

automatic focus position adjustment FocusLine

NitroLine high pressure cutting

fast processing with SprintLine in all sheet thicknesses

ContourLine for the production of small holes

automatic sheet outer edge detection

programmable power cycles

automatic nozzle cleaning

automatic shutdown

Workshop programming

6 clamping claws

Accessories:

several spare cutting nozzles from 0.8 mm to 2.7 mm

cleaning kit

various wear parts

Column-mounted slewing crane 500 kg with automatic trolley

aerolift sheet vacuum suction 170 kg

hot air exhaust funnel

Sheet metal storage racks are for sale as option.