Description

TSUGAMI BH38SY – Year 2010

CNC Swiss Lathe

Equipped with:

LNS Sprint 552-565 Magazine Bar Loader

Different Channel Sets – 14, 26, 33 & 39mm

LNS Turbo Chip Conveyor

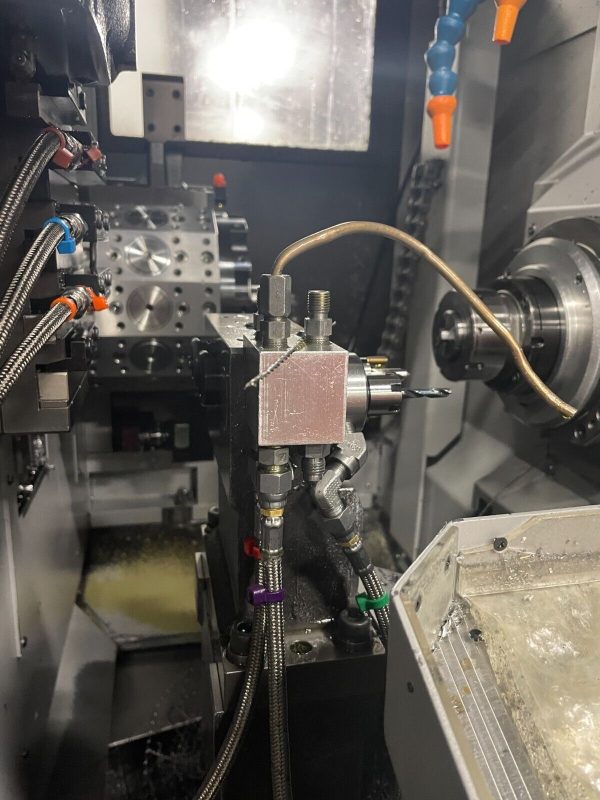

MP Systems, V2 Swiss, High Pressure Coolant System

Part Catcher / Part Conveyor

MISC Collets & Guide Bushings

Tri-Mist Mist Collector 850

Tooling includes (per attached photos to be confirmed by buyer):

(3) Powered Cross Drill,

(1) Double-ended 2-Pos Powered Face Drill;

(2) Double-ended 1-Pos Powered Face Drill,

(2) Double ID tool blocks,

(2) Single ID tool blocks,

(2) Double-turning holder,

(3) Front Holder

Ran only Oil

Ran mostly aluminum

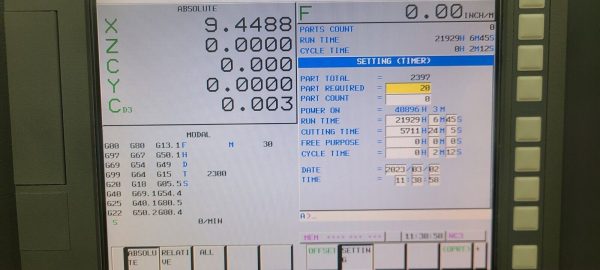

Hours: 22,049

GENERAL SPECIFICATION FOR A TSUGAMI BH38SY

Control: Fanuc 31i-A

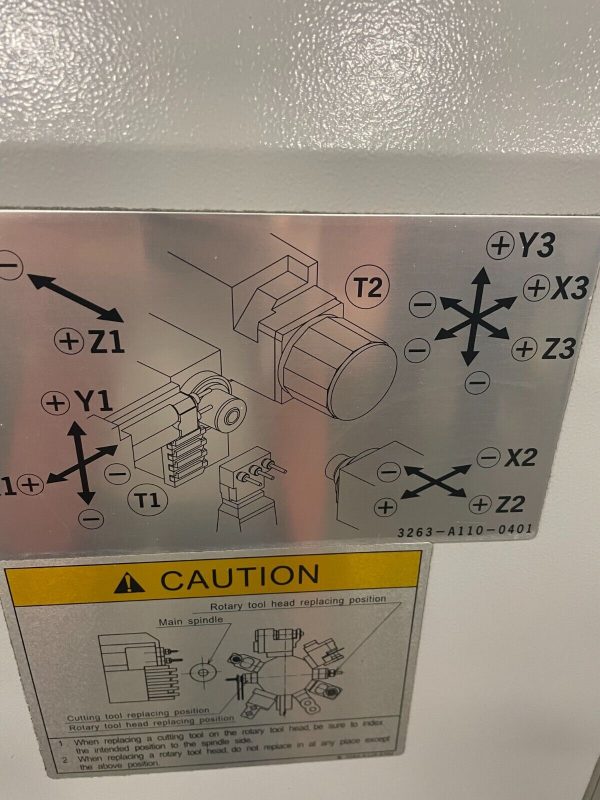

Axes: Front end:

Main Spindle: Z1, C1,

Sub Spindle: X2, Z2, C2

Gang plate: X1,Y1

Turret: X3,Y3,Z3

Headstock:

Turning Diameter Max: 1.496

Turning Length (in.) Max: 9.842

Bar Capacity (in.) Std: 1.500

Collet Type/Capacity: 1.625

Main Spindle: 6000 RPM

Motor: 15 HP

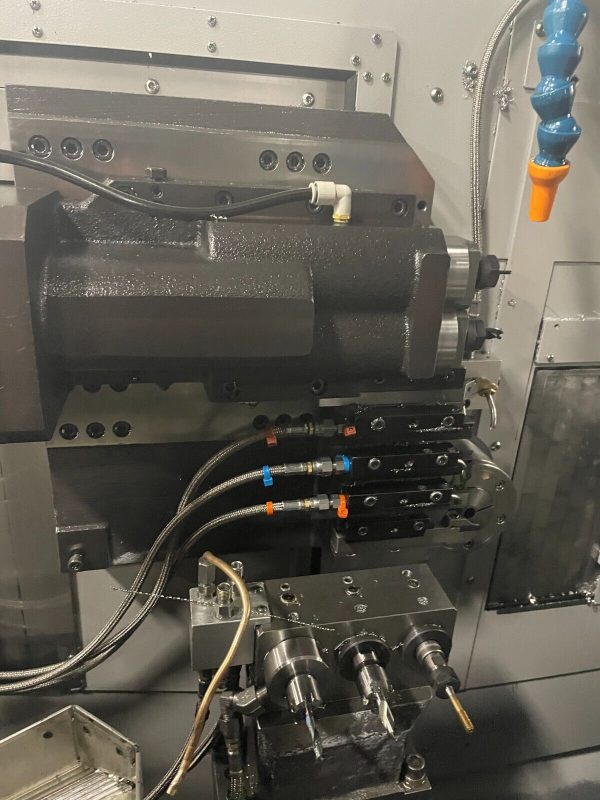

Sub-Spindle: (Standard) 5000 RPM

Sub spindle Motor: 7.30 HP

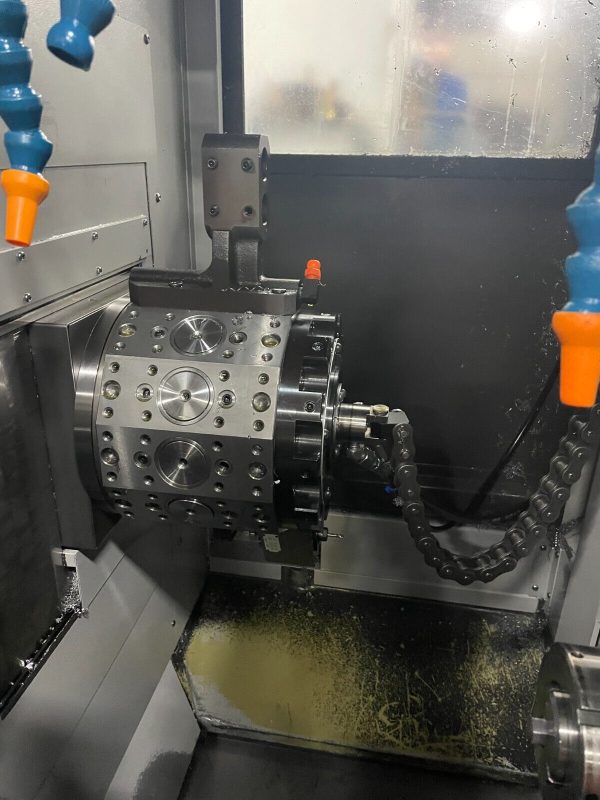

12-Station Turret

Max Tools 12 WITH 4 Rotary

Tool Shank Size (in.): Square: 0.750 Rotary: 0.393

Rotary Tool Spindle: 8,000 RPM

Rotary motor: 1.90 HP

Front Post

Max Tools 4 Turning plus 2 Rotary

Tool Shank Size (inch): Square: 0.625 Rotary: 0.310

Rotary Tool Spindle: 8000 RPM

Rotary Tool Power: 1.30 hp

WEIGHTS AND MEASURES

Length 107″ x 71″ x 67″H

Weight 13,000 lbs.

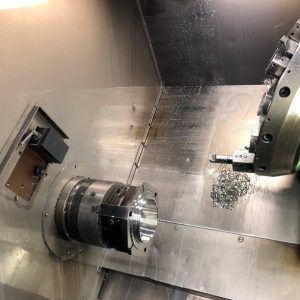

A combination turret / gang machine, the BH38SY combines all of the benefits

of a traditional Swiss turn with the flexibility and capability of a turret

machine. With 38mm (1-1/2″) main spindle capacity and a two axis sub spindle,

the BH38SY is one of the most able machines on the market.

The BH38SY’s 15HP main spindle has been constructed with Tsugami’s award

winning double-spindle design – allowing for maximum metal removal while

maintaining the most exacting tolerances. A 10HP, 2 axis sub spindle allows

for shortened cycle times. Its solid cast iron base provides superior

rigidity and cutting capabilities.