Description

VISION WIDE VB-2016 – Year 2013

CNC Double Column gantry milling machine

Technical specifications of the VISION WIDE VB-2016 CNC milling centre

number of axes: 3, 5 (after mounting of automatic head to vertical spindle)

work table surface (L x W): 2000 x 1300 mm

maximum workpiece weight: 8000 kg

feed rates in the X/Y/Z axis: 2000/1600/1020 mm

rapid traverse in X axis: 0-15000 mm/min

rapid traverse in Y axis: 0-15000 mm/min

rapid traverse in Z axis: 0-7000 mm/min

rotation of head around vertical axis C: automatic (indexing every 5°)

C axis positioning accuracy: ± 0,003°

maximum spindle speed of the automatic head: 3000 rpm

maximum spindle speed: 10000 rpm

maximum output spindle speed (with multiplier): 26000 rpm (20%ED)

maximum output spindle speed (with multiplier): 20000 rpm (80%ED)

maximum continuous output spindle speed (with multiplier): 16000 rpm (100%ED)

spindle power (continuous/momentary): 24/30 kW

maximum momentary spindle power (with multiplier): 9.5 kW (20%ED)

maximum distance between spindle tip and table: 1225 mm

minimum distance between spindle tip and table: 205 mm

spindle torque (continuous/momentary): 152/191 Nm

tool change time (tool-to-tool): 3 s

maximum tool diameter (adjacent pockets empty): 180 mm

maximum tool diameter (adjacent pockets occupied): 125 mm

maximum tool length: 380 mm

maximum tool weight: 18 kg

rotary table diameter: 800 mm

maximum load on rotary table (vertical position): 500 kg

maximum load of rotary table (horizontal position): 1000 kg

height of rotary table (vertical position): 880 mm

height of rotary table (horizontal position): 340 mm

distance between centre of rotary table disc and table stand (vertical position, rotation about horizontal axis): 480 mm

passage hole in the centre of the disc of the rotary table: d=254 mm

minimum indexing step of rotary table: 0,001°

manual tailstock of rotary table

distance between vertical gate pillars: 1700 mm

positioning accuracy (300 mm): ± 0.005 mm

full-length positioning accuracy: ± 0.015 mm

multiplier ratio: 1:5

multiplier attachment: ER16

multiplier holder: SK-50

machine switch on time: 8564 h

spindle operating time: 3027 h

programme execution operating time: 3271 h

axis operating time: 3454 h

dimensions (L x W x H): 7580 x 5355 x 4043 mm

rotary table weight: 1200 kg

VTEC VB 2016 machine weight: 25000 kg

Equipment of the CNC milling machine

CNC control: HEIDENHAIN iTNC 530

automatic swivel head (possibility of machining in 5 axes)

rotary table

workpiece probe: RENISHAW RMP-60

contact tool setting probe: RENISHAW TS 27R

X,Y,Z axis scales: HEIDENHAIN

32-position tool magazine

multiplier for speed multiplication of the main spindle

comprehensive tool set

screw chip conveyor (2 pieces)

transverse caterpillar chip conveyor

spindle taper: ISO-50/ DIN 69871

cooling through spindle

coolant pump: GRUNDFOS

cooling through tool centre for automatic head

sliding guideways

ball screw cooling system

liquid cooling system

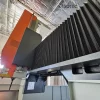

VISION WIDE VB-2016 5-AXIS CNC gantry milling machine was manufactured in 2013 in Taiwan. The machine performs precision machining of heavy workpieces in three or even five axes, once the automatic swivel head is mounted to the vertical spindle. The machine’s top-quality cast-iron structure is rigid and resistant to bending stress, thus perfectly dampening the vibrations and oscillations generated during machining.

The VISION WIDE VTEC VB 2016 CNC gantry milling machine centre is equipped with safety guards fitted around the entire machine with sliding doors that open flush with the X-axis travel. Inside, there is a large work table with a length of 2000 mm and a width of 1300 mm, which is supported along the entire length of the longitudinal travel and guided by two sliding guideways, making it possible to machine heavy workpieces even when the table is unevenly loaded.

Two screw chip conveyors and one transverse caterpillar chip conveyor with a discharge end at the end of the screw conveyors are arranged on both sides of the work table. A state-of-the-art HEIDENHAIN iTNC 530 CNC controller with all the necessary functions is used to program the machining modes and fully control the operation of the VISION WIDE VB-2016 machine.

Movements in the X,Y,Z axes are carried out using sliding guideways coated with Turcite B material, which ensures smooth movement and very high rigidity. In order to guarantee accurate positioning under changing conditions, the machine axes are additionally equipped with high-quality HEIDENHAIN scales. A special cooling system eliminates the effect of dilatation due to temperature rise, so the service life of all ball screws and bearings is significantly extended.

The spindle of the VISION WIDE 2000 x 1600 CNC milling machine, with a maximum power of 30 kW and a speed of 10000 rpm is located between two hydraulic cylinders. The cylinders are connected to an accumulator filled with compressed air to relieve the load on the Z-axis travel motor. Feed is carried out along the cross beam by means of two sliding guides placed symmetrically on both sides of the spindle.

The double column machining centre is offered with a wide range of equipment, consisting, among others, of a rotary table with a diameter of 800 mm, a RENISHAW RMP-60 workpiece probe, a RENISHAW TS 27R contact tool setting probe and a magazine for quick tool changes in the vertical position of the spindle with 32 positions. The total weight of the machine is 25000 kg. The gantry machining centre has so far worked a small number of hours machining small parts.