Description

Voumard 300 – Year 2003

CNC Universal ID/OD CNC Grinder

SPECIFICATIONS:

O.D. Grinding (max)(inch): 21.653

I.D. Grinding (min): 0.039

I.D. Grinding (max, inch): 19.685

O.A. Grinding L. (inch): 29.527

Workpiece weight (max, lbs): 1,100

Longitudinal Travel (inch): 39.3

Cross Travel (inch): 11.81

Machine Weight (lbs): 17,600

O.D. Grinding (max)(inch): 21.653

EQUIPPED WITH:

Full Enclosures

Siemens CNC Control

MORE ABOUT THIS MACHINE:

The Voumard 300 CNC Large Capacity Production Center Grinder Grinding of short workpieces in a chuck or centerless system, long shafts in a steady rest. 4-position NC indexing wheel spindle turret enabling internal or external grinding operations. Manual or automatic loading. Optionally – U Axis work head cross slide to increase the OD grinding capacity B Axis work head swiveling for taper grinding. C Axis work head spindle rotation control for cam or thread grinding D Axis complementary axis dresser point rotation control.

Manufacturer Catalogue Information about VOUMARD VM 300 Series :

High Productivity and Flexibility Solutions

Universal ID/OD grinding machine for large sized work pieces

VOUMARD VM 300

Latest Technology as Standard –

Highest Precision for all Materials and Industries

The VOUMARD VM 300 is a universal ID / OD grinding tool specifically designed for machining work pieces with large diameters and/or lengths.The large working space in combination with the extended travelling distance of the spindle head and the optional U-axis provide highest loading capacity and process flexibility.While short work pieces can be ground directly when clamped in the chuck, a variety of manual and automatic steady rests is available for grinding operations with long shafts.

Typical applications are grinding operations on parts for: • Hydraulic components

• Spindles

• Bearings

• Gears

Equipment:

• Four position NC indexing spindle turret permits mul-tiple ID/OD grinding operations with different grinding

wheels at the same work piece and combines maximum flexibility with highest grinding accuracy

• Optional U-axis for extended OD grinding range

• High precision X- and Z-axis with large travel distances for

maximum flexibility

• Manual or numerical controlled B-axis for angular swivel of the

workhead for taper grinding and easier access when loading and

unloading large work pieces

• Optional work head spindle indexing (C-axis)

• Various dressing tools for conventional and CBN grinding wheels,

including a radius dresser for high precision grinding of circular

profiles

• Heavy duty work head spindle with a load capacity of up to

500kg

Control:

• Siemens CNC with proprietary VOUMARD graphical user interface

• Offline programming tool on external computer minimizes downtime when creating new grinding sequences

• Remote diagnosis system for quick trouble shooting

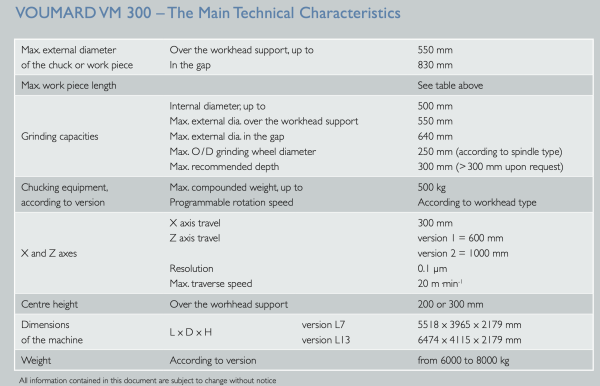

VOUMARD VM 300 – The Main Technical Characteristics

Max. work piece length

See table above

</table border=”1″>

Centre height Weight

Over the worhhead support According to version

200 or 300 mm

from 6000 to 8000 kg

workshops of market-leading companies in major industry seg- ments like automotive, aerospace, bearing, tooling and spindle manufacturing.

VOUMARD systems are suitable for a large variety of parts manu- factured in large batches (like diesel common rail and hydraulics- pneumatics components) or low quantities (like high precision bearings and machines spindles components).

Internal and External Grinding Perfection

VOUMARD high productivity grinding machines are designed for flexible ID and OD grinding operations. Highly accurate chucks and centerless work holding solutions allow for processing work pieces of almost every geometry and performing multiple internal and external grinding operations in a single clamping.

The VOUMARD machine range provides every customer with both high productivity and high flexibility

grinding solutions. Our machines are appreciated

worldwide and integrated in production lines or manufacturing

workshops of market-leading companies in major industry seg- ments like automotive, aerospace, bearing, tooling and spindle manufacturing.

VOUMARD systems are suitable for a large variety of parts manu- factured in large batches (like diesel common rail and hydraulics- pneumatics components) or low quantities (like high precision bearings and machines spindles components).

|

Max. external diameter |

Over the workhead support, up to In the gap |

550 mm 830 mm |

|

|

Grinding capacities |

Internal diameter, up to |

500 mm |

|

|

Chucking equipment, Max. compounded weight, up to 500 kg |

|||

|

X and Z axes |

X axis travel Z axis travel Resolution |

300 mm |

|

|

Dimensions |

L x Dx H |

version L7 version L13 |

5518 x 3965 x 2179 mm 6474 x 4115 x 2179 mm |