Description

Walter Helitronic Power 400 5-OSI

CNC Tool Grinder 5 Axis

| Max. grinding length | 520 mm |

| Grinding diameter | 315 mm |

| Exter | Yes |

| Inter | Yes |

| CNC | Yes |

| Type of CNC | Fanuc |

| Max. wheel speed | 10500 rpm |

| Spindle motor power | 24 kW |

| Walter Helitronic Power 400 5-OSI | CNC Tool Grinder 5 Axis |

| Length x width x height | 2700.0 × 1691.0 × 2640.0 |

| Weight | 5300 kg |

| Worked hours | 1200 hours |

| Hours under power | 9000 hours |

Technical data of the WALTER HELITRONIC POWER 400 5-AXIS CNC grinding machine

– 5 axes (X, Y, Z, C, A)

– feeds in the X / Y / Z axes: 650/350/720 mm

– feed in the rotary axis C: 400 °

– feed in the rotary axis A: ∞ °

– maximum accelerated feeds in the X, Y, Z axes: 15 m / min

– accuracy of spatial positioning in the axes: 0.0001 mm

– spatial positioning accuracy in rotary axes: 0.0001 °

– maximum length of the detail (peripheral grinding): 520 mm

– maximum workpiece length (face grinding): 380 mm

– minimum tool diameter: 3 mm

– maximum tool diameter: 315 mm

– maximum workpiece weight: 50 kg

– maximum diameter of the grinding wheel: 254 mm

– spindle speed: 0-10500 rpm

– spindle diameter: 80 mm

– spindle power: 24 kW

– contact probe diameter: 25 mm

– spindle working hours: 1200 h

– hours of connecting the machine to electricity: approx. 9000 h

– total power requirement: approx. 25 kVA

– POWER 400 machine dimensions (length x width x height): 2700 x 1691 x 2640 mm

– total weight: approx. 5300 kg

Accessories for the WALTER HELITRONIC POWER 400 grinding machine

– CNC control: FANUC

– CAD / CAM software: HELITRONIC TOOL STUDIO

– contact probe: RENISHAW MP250

– tool holder: HSK 50

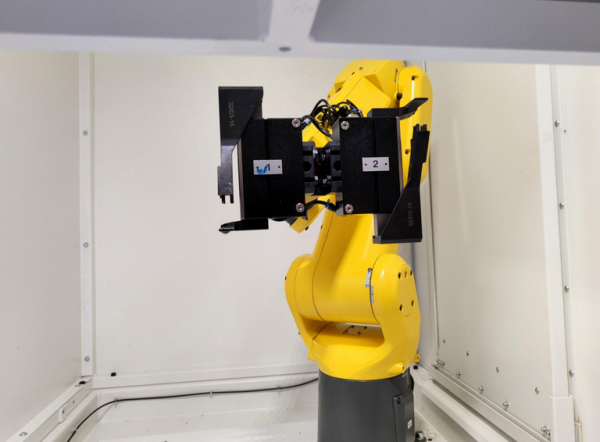

– robot for loading / unloading details

– cooling system with aggregate and filter

– tool palette fi 12 (2 pcs.)

– automatic collet chuck system

– a set of tools for suction of water mist

– fire extinguisher

WALTER HELITRONIC POWER 400 5-AXIS CNC grinding machine was manufactured in 2017 in Germany. The purpose of the machine is fully automatic grinding of tools used in various industries in five axes (X, Y, Z, C, A). The workpieces can be up to 50 kg in weight and 380 mm long (in face grinding) or 520 mm long (in peripheral grinding).

The construction of the grinder with increased stiffness, made of solid gray cast iron, effectively reduces vibrations generated during the grinding process, significantly improving the precision and quality of machining. The machine is characterized not only by high-quality processing, but also by modern design and a high-class FANUC CNC controller with a convenient control panel.

The offered five-axis CNC grinder has a wide range of equipment, including: with the RENISHAW MP250 contact probe for reliable measurements in all conditions, the spindle rotating at a maximum speed of 10500 rpm, or the CAD / CAM HELITRONIC TOOL STUDIO software for designing and editing all tool parameters. The total weight of the machine is approximately 5,300 kg.