Description

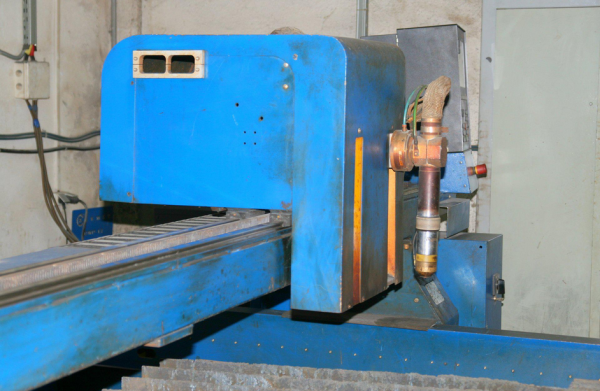

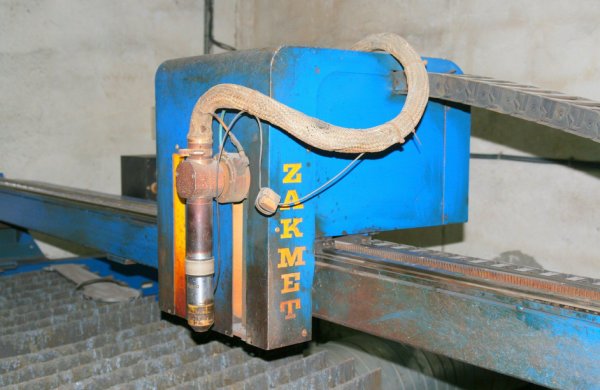

ZAKMET HYPERZAKMET 6000×2500 – Year 2008

| Metal length | 6000 mm |

| Metal width | 2500 mm |

| Max steel thickness | 38 mm |

| Type of source | Plasma |

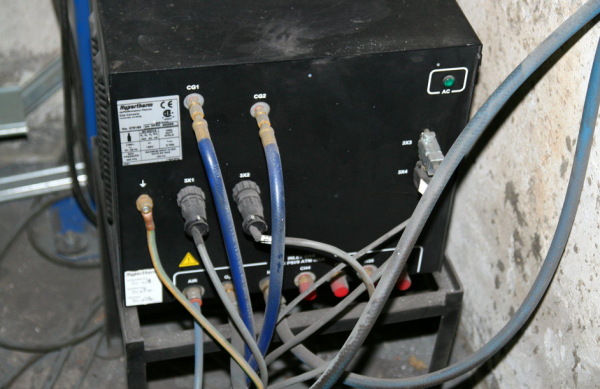

| Source model | HYPERTHERM HyPerformance HPR 130 |

| CNC | Yes |

| Type of CNC | HYPERTHERM EDGE |

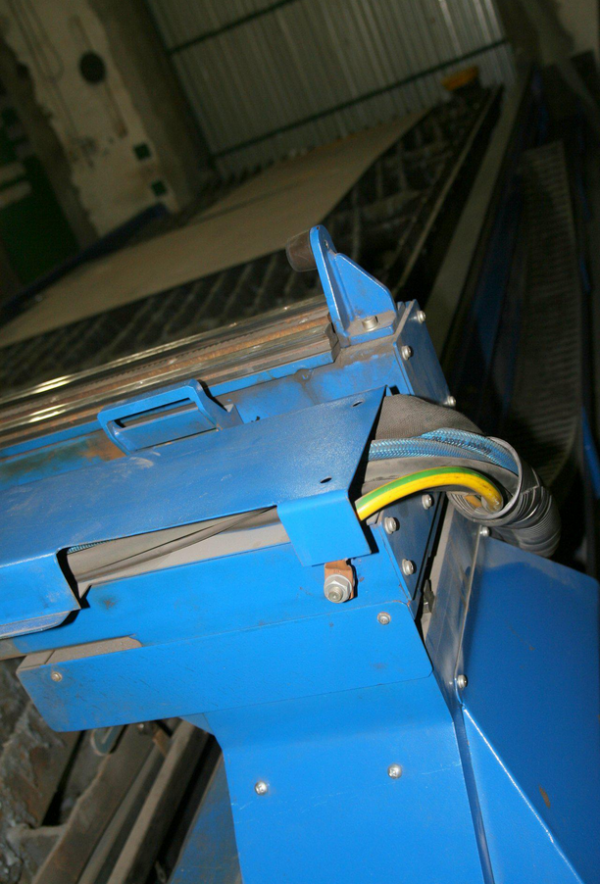

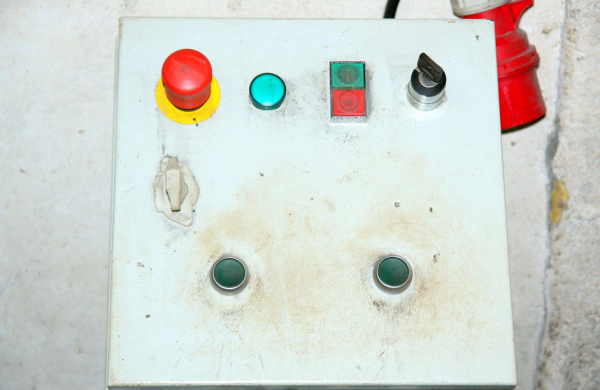

The process of cutting details is performed on a high-quality working table of a plasma burner, 6000 mm long and 2500 mm wide, with the possibility of extension by means of an additional control panel. The combination of high rigidity and stability of machining with a high cutting speed of up to 4950 mm / min guarantees the best results in a short time.

The plasma cutter is also equipped with, among others with a modern CNC HYPERTHERM EDGE controller for full control over the operation of the machine and CAD / CAM FASTCAM software, which allows you to program the cut shapes in the simplest and most effective way.

Technical data of the plasma cutter ZAKMET HYPERZAKMET 6000×2500

– working area (L x W): 6000 x 2500 mm

– maximum cutting thickness (carbon steel): 38 mm

– maximum cutting thickness (stainless steel): 20 mm

– maximum cutting thickness (aluminum): 20 mm

– cutting speed: 250-4950 mm / min

– travel speed: 50-8000 mm / min

– working table height: 600 mm

– type of table: retractable, on tracks (control via an additional desktop)

– laser source output current: 130 A

– power supply: 230 V; 50 Hz

Equipment of the plasma burner ZAKMET HYPERZAKMET 6000×2500

– CNC controller: HYPERTHERM EDGE

– laser source: HYPERTHERM HyPerformance HPR 130

– CAD / CAM software: FASTCAM (with dongle)

– gas console

– ignition console

– refrigeration dryer

– table extension control panel

– exhaust fan