Description

| Zeiss Accura 12/18/10 Measuring unit | |

| Length x width x height | 2197.0 × 2540.0 × 3550.0 |

| Weight | 5900 kg |

Technical data for the ZEISS ACCURA 12/18/10 portal measuring machine

– software: ZEISS CALYPSO

– measuring head: VAST XTR GOLD

– maximum permissible length measurement error MPEE0: 1.8 + L / 350 µm

– the maximum allowable limit of the repeatability range MPLR0: 1.5 µm

– measurement error of the shape of a single MPEPFTU stylus: 1.7 µm

– RONT shape measurement error: 1.7 µm

– maximum permissible measuring error of MPETHP scanning: 2.9 µm T: 40 s

– measuring range in the X / Y / Z axes: 1200/1800/1000 mm

– maximum scanning speed: 200 mm / s

– measurement resolution: 0.2 µm

– maximum workpiece weight: 2000 kg

– working area (L x W x H): 1590 x 2540 x 1604 mm

– working table height: 604 mm

– 3-level tool magazine

– pallet loading system with active temperature measurement of the measured detail

– ambient temperature: 20-26 ° C

– working pressure: 0.5 MPa

– total power requirement: 1600 VA

– dimensions (length x width x height): 2197 x 2540 x 3550 mm

– total weight of the ACCURA 12/18/10 machine: 5900 kg

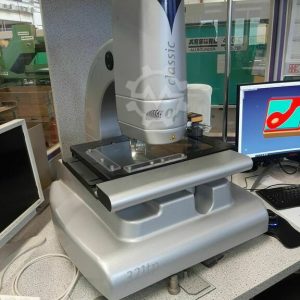

ZEISS ACCURA 12/18/10 measuring machine, manufactured in 2019 in Germany, is used to perform geometric measurements of machine and automotive elements. The measurement is performed on details weighing a maximum of 2000 kg, in three X / Y / Z axes with ranges of 1200 mm, 1800 mm and 1000 mm, respectively.

The machine belongs to the group of CMM (coordinate measuring machine), characterized by the highest accuracy and objectivity. In this type of machines, the dimensions of a given detail taken by the measuring head are perceived as a set of coordinates of points on a contact or non-contact path. Thanks to the use of this technique, it is possible to measure objects with complex shapes that cannot be measured with basic measuring instruments, such as a caliper or a length gauge.

The extremely rigid portal of the measuring machine was made in a special CARAT (Coating Aging Resistant Aluminum Technology) technology, ensuring an improvement in temperature stability and an increase in measuring speed by maintaining an ideal mass-to-volume ratio. The portal CMM is equipped with a VAST XTR GOLD rotary measuring head, a 3-level tool magazine and a pallet loading system with active (maintenance-free) temperature measurement of the measured product.

Currently, the machine is configured to automatically measure elements in the process: GSE T3 / T4 body, T3 / 4 head, T3 / T4 crankshaft. The total weight of the measuring machine is 5,900 kg.