What is CNC Spline Rolling Machine?

CNC Spline Rolling Machine – Technical Explanation

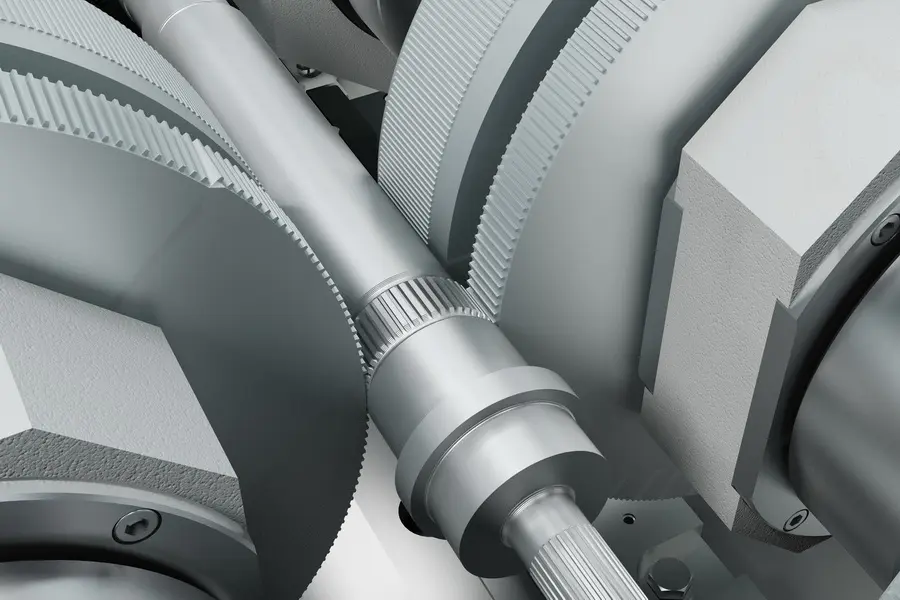

A CNC Spline Rolling Machine is a computer-controlled precision metal forming machine used to produce splines, serrations, and threads on shafts and cylindrical components. Instead of cutting material like traditional machining methods, spline rolling machines use cold forming techniques to plastically deform the workpiece, creating precise spline profiles with superior strength and surface finish.

1. Working Principle of a CNC Spline Rolling Machine

A CNC Spline Rolling Machine forms splines using cold rolling instead of cutting, which enhances material properties. The process involves the following key steps:

1.1. Workpiece Loading

- The cylindrical blank (shaft or tube) is loaded into the machine, either manually or through an automated feeding system.

1.2. Rolling Die Positioning

- The machine has two or three precision-ground spline rolling dies that rotate in synchronization.

- These dies have negative impressions of the desired spline profile.

1.3. Cold Forming Process

- The workpiece is placed between the rotating dies, and high compressive force is applied.

- As the dies rotate, they plastically deform the surface of the workpiece, gradually forming the spline pattern.

- The material flows into the die cavities, ensuring precise geometry and uniformity.

1.4. CNC-Controlled Precision

- The entire process is controlled by a CNC system, ensuring:

- Accurate rolling speed and force control

- Consistent spline dimensions

- High repeatability for mass production

1.5. Unloading & Quality Inspection

- Once the spline is formed, the finished part is automatically unloaded.

- Optical or CNC measuring systems verify dimensional accuracy and profile integrity.

2. Key Components of a CNC Spline Rolling Machine

2.1. CNC Control System

- Provides high precision control of rolling force, speed, and die positioning.

- Allows for programmable adjustments for different spline profiles.

2.2. Rolling Dies

- Made from hardened tool steel or carbide, designed specifically for the required spline pattern.

- Configurations:

- Two-Die System (Radial Rolling)

- Three-Die System (More even pressure distribution, better accuracy)

2.3. Hydraulic or Servo Drive System

- Provides the necessary rolling force (can be 100-500 kN, depending on machine capacity).

- Servo-driven models offer finer control over force and position.

2.4. Workpiece Holding System

- Self-centering chucks or automated loading systems ensure precise alignment.

2.5. Cooling & Lubrication System

- Reduces friction and tool wear, improving surface finish and tool lifespan.

3. Advantages of CNC Spline Rolling vs. Traditional Machining

4. Applications of CNC Spline Rolling Machines