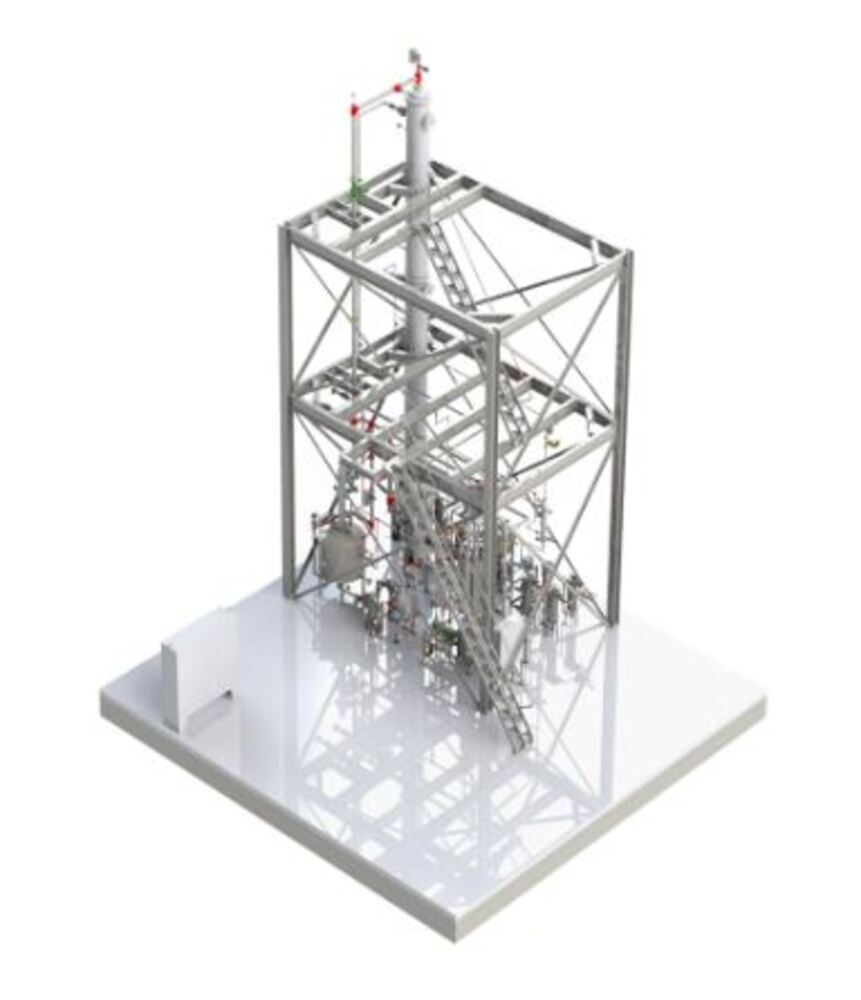

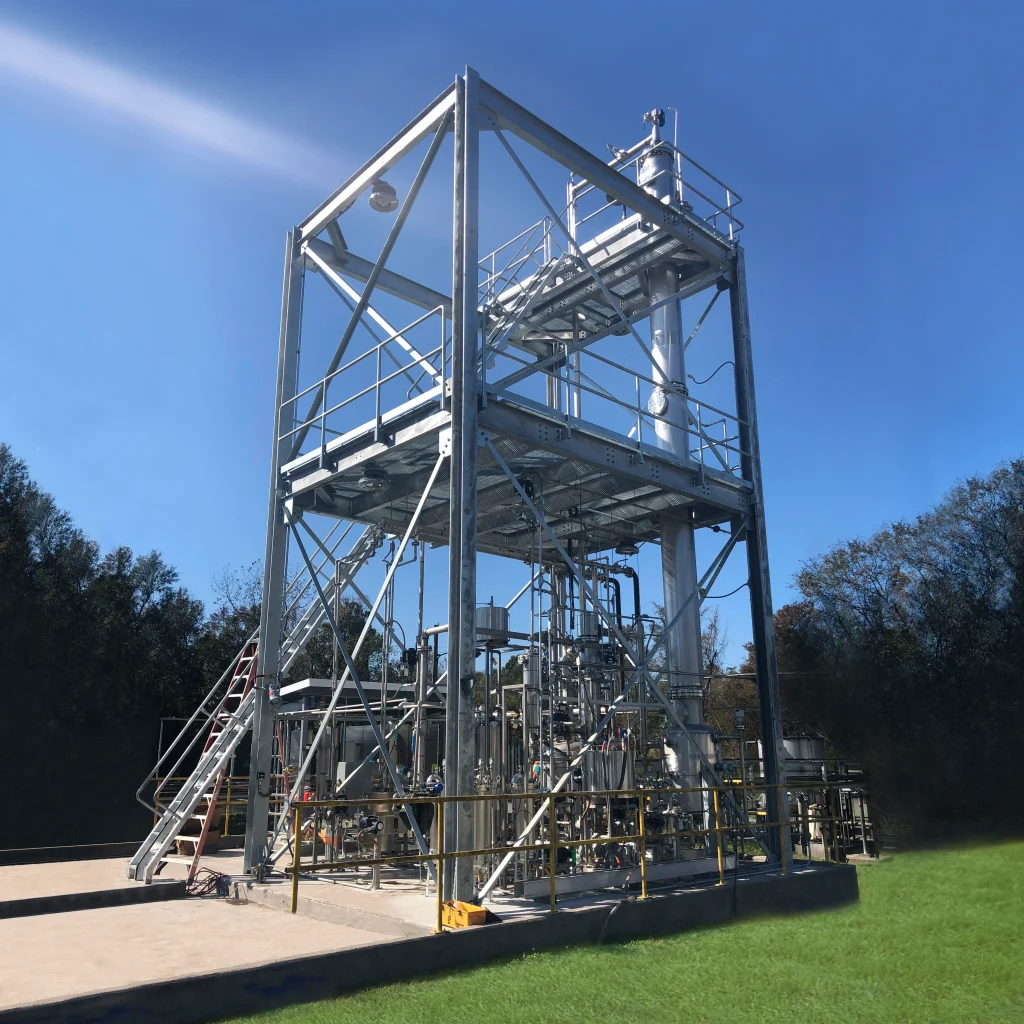

What is Fractional Distillation Column Equipment For Purification, Fractionation, Distillation, Reproofing – Separating Solvents from Liquid Blends and Mixtures?

Fractional Distillation Column Equipment: Technical Explanation

Fractional distillation column equipment is an industrial separation system designed for purification, fractionation, distillation, and reproofing of liquid mixtures by selectively separating components based on boiling points. It is widely used in industries like chemical processing, petroleum refining, pharmaceuticals, and solvent recovery.

1. Working Principle of Fractional Distillation

Fractional distillation operates on the principle that different liquids in a mixture have different boiling points. By carefully controlling temperature and pressure, the system separates components based on their volatility.

Step-by-Step Process:

- Feed Introduction:

- The liquid blend is fed into the column at a specific location (called the feed tray or feed stage).

- Heating in Reboiler:

- A reboiler heats the mixture, converting the more volatile components into vapor while leaving the heavier components as liquid.

- Vapor-Liquid Contact & Separation:

- The vapor rises through the fractionating column, which contains multiple trays or packing materials that promote vapor-liquid contact.

- As vapor rises, it cools, and components with higher boiling points condense back into liquid, while lower-boiling-point components continue to rise.

- Fraction Collection:

- The column is designed with multiple collection points (draw-off trays or side streams) to extract specific fractions at controlled temperatures.

- Lighter fractions exit at the top condenser, while heavier fractions remain at the bottom for reboiling or further processing.

- Reflux System (Enhancing Separation Efficiency):

- A portion of the condensed liquid (distillate) is sent back into the column to improve purity by allowing multiple separation cycles.

2. Key Components of a Fractional Distillation Column

| Component | Function |

|---|---|

| Reboiler | Heats the mixture to generate vapor for separation. |

| Fractionating Column | Contains trays or packing to allow vapor-liquid interaction. |

| Trays/Packing Material | Enhances separation by maximizing surface area for vapor-liquid contact. |

| Condenser | Cools and condenses purified vapors into liquid fractions. |

| Reflux System | Returns part of the condensed liquid back into the column to improve separation efficiency. |

| Feed Entry Point | Location where the raw mixture is introduced into the column. |

| Distillate Collection System | Collects the purified solvent or product at different stages. |

3. Applications of Fractional Distillation Equipment

This technology is used in various industries for solvent separation, purification, and chemical processing:

(a) Solvent Recovery & Separation

- Removing impurities from solvents (e.g., ethanol, acetone, methanol).

- Purifying recycled solvents used in manufacturing processes.

(b) Chemical & Pharmaceutical Industry

- Separation of organic compounds in fine chemical synthesis.

- Purification of active pharmaceutical ingredients (APIs).

(c) Petroleum & Fuel Processing

- Refining crude oil into gasoline, diesel, and kerosene.

- Reproofing (re-distilling) ethanol to remove water and impurities.

(d) Alcohol & Beverage Industry

- Distilling spirits such as whiskey, vodka, and rum.

- Reproofing ethanol to increase purity levels.

4. Fractional Distillation vs. Simple Distillation

| Feature | Fractional Distillation | Simple Distillation |

|---|---|---|

| Complexity | Uses multiple trays or packing for enhanced separation | Single stage separation |

| Purity | Produces high-purity fractions | Limited separation capability |

| Efficiency | Reflux system allows repeated separation cycles | Only one vaporization-condensation cycle |

| Applications | Used for multi-component mixtures | Suitable for separating liquids with large boiling point differences |

5. Advantages of Fractional Distillation Column Equipment

Conclusion

A Fractional Distillation Column is a critical piece of equipment for separating, purifying, and reproofing solvents and liquid mixtures based on their boiling points. It is widely used in chemical processing, petroleum refining, pharmaceutical production, and alcohol distillation. By leveraging multi-stage vapor-liquid interaction, it ensures high-purity output, efficient solvent recovery, and reduced operational costs.