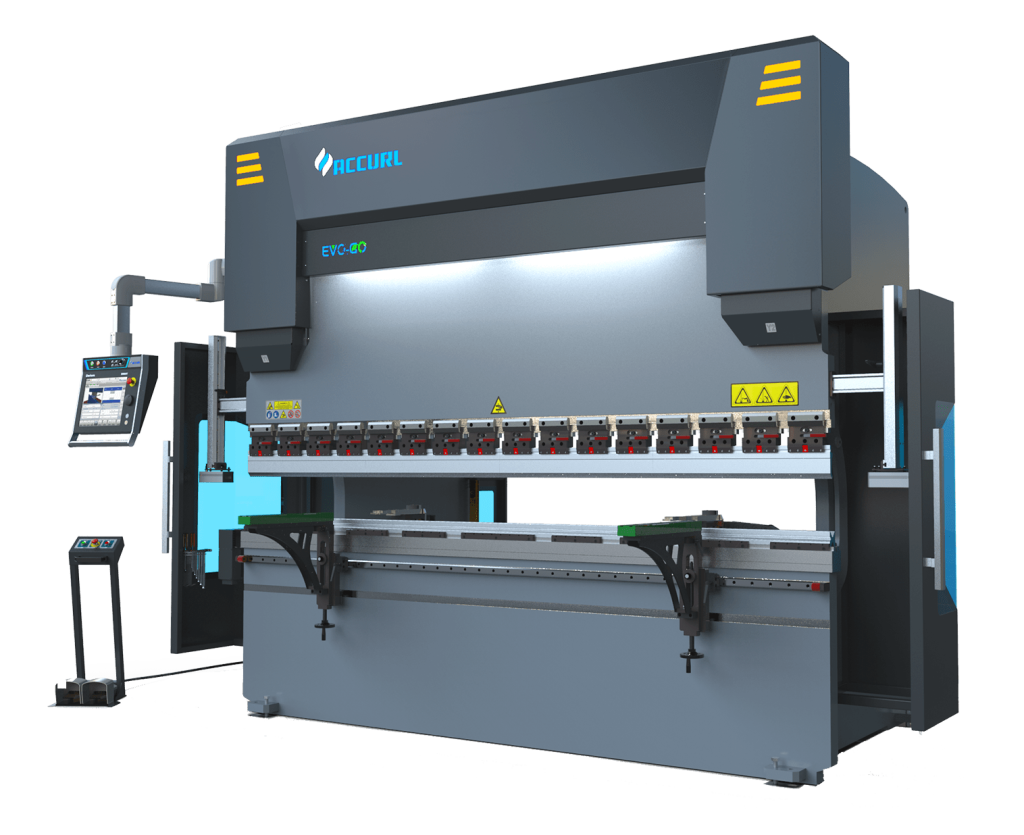

What is Hybrid 8-Axis CNC Press Brake?

A Hybrid 8-Axis CNC Press Brake is an advanced sheet metal forming machine designed for bending and shaping metal sheets using a combination of hydraulic and electric drive systems. The term “8-axis” refers to the number of independent movements the machine can perform, allowing for precise control over the bending process and complex part geometries.

Key Components of a Hybrid 8-Axis CNC Press Brake

- Hybrid Drive System:

- Combines hydraulic and electric systems for optimal performance:

- Hydraulic System: Provides the force needed for heavy-duty bending operations.

- Electric System: Ensures precision and energy efficiency for positioning and movement.

- Combines hydraulic and electric systems for optimal performance:

- 8 Axes of Motion:

- The axes typically include:

- X1 and X2: Control the position of the back gauge in the horizontal direction.

- R1 and R2: Adjust the height of the back gauge for variable material thickness.

- Z1 and Z2: Move the back gauge fingers laterally for flexible setups.

- Y1 and Y2: Control the movement of the upper beam (ram) for independent control of each side, ensuring parallelism and precision.

- The axes typically include:

- CNC Control System:

- A computer numerical control (CNC) unit manages all movements and settings, allowing for:

- High precision in bends.

- Automated tool changes.

- Storage of bending programs for repeatable accuracy.

- Graphical interfaces for ease of programming and operation.

- A computer numerical control (CNC) unit manages all movements and settings, allowing for:

- Advanced Features:

- Crowning System: Ensures uniform bending by compensating for deflection in the ram or table.

- Tooling Systems: Compatible with precision-ground tools for complex bends.

- Safety Systems: Includes laser guarding or light curtains for operator safety.

- Frame and Construction:

- Rigid construction minimizes deformation during bending.

- High-quality materials and advanced manufacturing processes increase durability and accuracy.

Advantages of a Hybrid 8-Axis CNC Press Brake

- Energy Efficiency:

- The hybrid system uses energy only during active bending, reducing operational costs.

- Precision:

- Multiple independent axes allow for precise control of material positioning and bending angles.

- Versatility:

- Suitable for complex part geometries and multi-step bending processes.

- Reduced Maintenance:

- Electric drives require less maintenance than purely hydraulic systems.

- High Productivity:

- Quick setup times and automated processes enable high-speed production with consistent quality.

Applications

Hybrid 8-axis CNC press brakes are widely used in industries such as:

- Automotive: For precision parts and body panels.

- Aerospace: For lightweight and intricate sheet metal components.

- Electronics: For enclosures and chassis.

- Construction: For structural elements and decorative panels.

This combination of hybrid technology and multi-axis control makes the Hybrid 8-Axis CNC Press Brake a powerful tool for modern manufacturing environments, where precision, efficiency, and versatility are paramount.