03/04/2025

What is Induction Bending, High-Frequency Bending Machine?

Induction Bending – Technical Explanation:

Induction Bending – Technical Explanation:

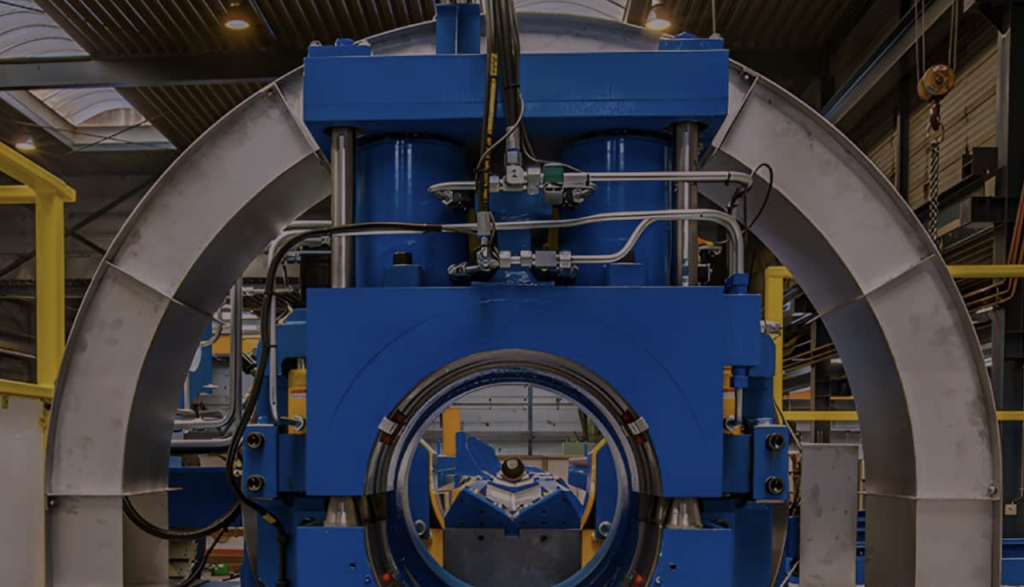

Induction bending is a precise and efficient method for bending pipes, tubes, or profiles using localized heating by electromagnetic induction.

How It Works:

How It Works:

- Induction Coil Placement:

A high-frequency induction coil is placed around the section of the pipe where the bend is required. - Localized Heating:

The coil generates an alternating magnetic field that induces eddy currents in the metal, causing it to heat up rapidly—usually to 850–1100°C (depending on material type). - Bending Arm Mechanism:

Once the material is heated to plastic deformation temperature, a mechanical arm pushes the pipe through a fixed radius die to create a smooth bend. - Cooling (Quenching):

After bending, forced air or water spray is applied to cool and set the bend, preventing distortion or spring-back.

Technical Advantages:

Technical Advantages:

- No thinning or wrinkling of pipe wall (maintains wall thickness).

- Accurate bend radius, from 5D to 100D or more.

- Large diameter pipes (up to 1,200 mm or more) can be bent.

- No need for internal mandrels or external dies.

- Suitable for carbon steel, stainless steel, alloy steel, and titanium.

High-Frequency Bending Machine:

High-Frequency Bending Machine:

A High-Frequency (HF) Bending Machine is a type of induction bending system that uses high-frequency (typically 3–100 kHz) alternating current to heat the material.

Technical Features:

Technical Features:

- High-Frequency Generator: Produces the electromagnetic field.

- Precise Temperature Control: Allows controlled, repeatable heating cycles.

- CNC/PLC Systems: Automates the bend angle, heating duration, feed rate, and quenching.

Where It’s Used:

Where It’s Used:

- Pipeline construction (oil, gas, water).

- Shipbuilding & offshore structures.

- Power plants (nuclear and thermal).

- Structural and architectural fabrication.

- Automotive & aerospace (for custom exhaust or structural components).

Summary:

Summary:

| Feature | Induction Bending | High-Frequency Bending Machine |

|---|---|---|

| Heating method | Electromagnetic induction | High-frequency AC induction |

| Material types | Carbon steel, alloy steel, etc. | Same (with precision control) |

| Bend precision | High | Very high (CNC controlled) |

| Wall deformation | Minimal | Extremely minimal |

| Typical applications | Industrial piping, structures | High-precision industries |