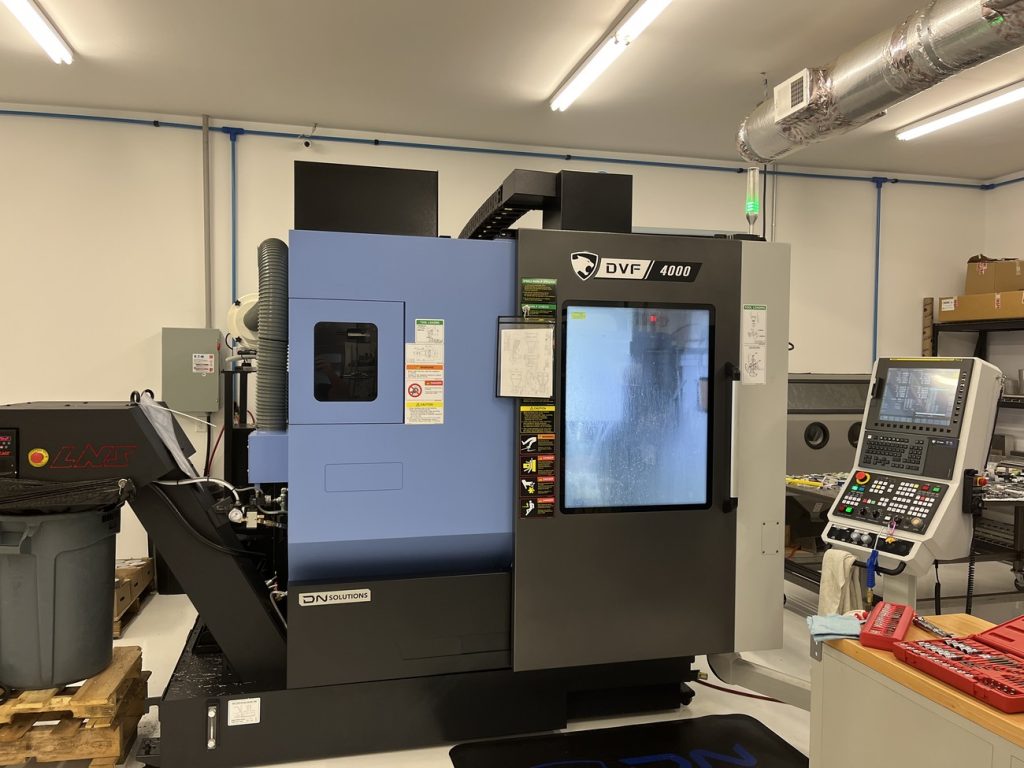

Why do Customers prefer using DN Solutions DVF 4000 CNC 5-Axis Vertical Machining Center that is solution for complex shapes made in South of Korea?

Customers prefer using the DN Solutions DVF 4000 CNC 5-Axis Vertical Machining Center for a variety of reasons related to its advanced technical capabilities and financial benefits. Here’s a detailed explanation:

Technical Reasons

- Complex Shape Machining:

- The DN Solutions DVF 4000 is specifically designed for machining complex shapes and intricate geometries. Its 5-axis capability allows for simultaneous movement along multiple axes, enabling the creation of highly detailed and accurate parts in a single setup.

- Precision and Accuracy:

- The machine offers exceptional precision and accuracy, which is crucial for industries such as aerospace, automotive, medical devices, and mold making. High-quality components and advanced control systems ensure that the finished parts meet stringent tolerances.

- Versatility:

- The DVF 4000 can handle a wide range of materials, including metals like aluminum, titanium, and stainless steel, as well as composites and plastics. This versatility makes it suitable for various applications and industries.

- Advanced Control Systems:

- Equipped with state-of-the-art CNC controls, the machine provides easy programming, real-time monitoring, and adaptive control. These features enhance usability, reduce the learning curve for operators, and ensure consistent performance.

- Enhanced Productivity:

- The ability to perform multiple operations in a single setup reduces the need for multiple machines and setups. This streamlines the manufacturing process, reduces cycle times, and increases overall productivity.

- Robust Construction:

- Built with high-quality materials and robust construction, the DVF 4000 offers durability and reliability. It is designed to operate under demanding conditions, providing consistent performance and longevity.

- Integrated Automation:

- The machine can be integrated with automation systems such as robotic arms and pallet changers, further enhancing productivity and enabling continuous, unattended operation.

Financial Reasons

- Cost Efficiency:

- While the initial investment in a 5-axis machining center can be high, the DN Solutions DVF 4000 offers long-term cost efficiency. Its ability to perform complex machining tasks in a single setup reduces overall production costs and increases return on investment (ROI).

- Increased Throughput:

- The machine’s advanced capabilities and high-speed performance result in increased throughput. Higher production volumes can lead to greater revenue potential and faster ROI.

- Reduced Labor Costs:

- The advanced automation and user-friendly controls reduce the need for skilled labor. The machine’s ability to operate autonomously for extended periods also lowers labor costs.

- Lower Maintenance Costs:

- The robust design and high-quality components of the DVF 4000 result in lower maintenance requirements and costs. The machine’s reliability minimizes downtime, contributing to overall cost savings.

- Material Savings:

- The precision and accuracy of the DVF 4000 minimize material waste. High-quality machining means fewer defects and rework, optimizing material usage and reducing costs.

- High Resale Value:

- Machines from DN Solutions are known for their durability and reliability, ensuring a high resale value. Businesses can recover a significant portion of their investment if they decide to upgrade or sell the machine in the future.

Conclusion

Customers prefer the DN Solutions DVF 4000 CNC 5-Axis Vertical Machining Center for its superior technical capabilities, including the ability to machine complex shapes, precision and accuracy, versatility, advanced control systems, enhanced productivity, robust construction, and integrated automation. Financially, the machine offers cost efficiency, increased throughput, reduced labor and maintenance costs, material savings, and high resale value. These factors make the DVF 4000 a valuable investment for companies involved in high-precision and complex machining operations.

5-Axis VMC to Vertical Machining Center

DVF 4000 5-axis machining centres are designed for component manufacturers looking to machine high-precision, complex parts in one hit. Equipped with leading edge technology and supplied ‘automation- ready’, these machines will take your productivity and performance to a whole new level.

Solutions for complex shapes

12000 / 18000 r/min high-speed spindle

2-axis tilting table from Ø400 mm to Ø800

Table turning function : DVF 6500T / DVF 8000T

High torque spindle of 426 N.m : DVF 8000T/50