Why do Customers prefer using Nissei ASB-70DPW is a mid-sized one-step injection stretch blow molding machine made in Japan?

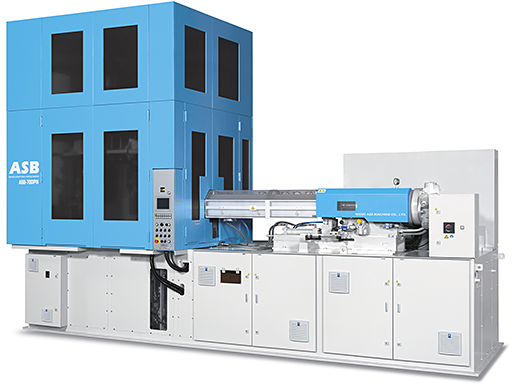

The Nissei ASB-70DPW is a mid-sized one-step injection stretch blow molding (ISBM) machine manufactured in Japan. It is widely preferred by customers for various technical and practical reasons, especially in industries requiring the production of high-quality, complex-shaped plastic containers, such as in the food, beverage, pharmaceutical, and cosmetic sectors.

Technical Explanation and Advantages

- One-Step Process:

- The ASB-70DPW is a one-step ISBM machine, meaning it integrates the injection molding and blow molding processes into a single machine. This allows for the production of containers directly from raw materials in one continuous process, enhancing production efficiency and reducing the need for intermediate handling or storage.

- The one-step process is particularly beneficial for producing containers with complex shapes or requiring high precision, as it minimizes the risk of contamination and deformation.

- Dual-Station Design:

- The “DPW” in ASB-70DPW stands for Dual-Station, meaning the machine features two separate stations for injection and blow molding. This dual-station design increases productivity, allowing the machine to handle higher output rates while maintaining consistent quality.

- Versatility in Material and Design:

- The machine is capable of handling a wide range of materials, including PET, PP, PC, and various other thermoplastics. This versatility makes it suitable for producing containers with different properties, such as barrier layers for extended shelf life or heat-resistant containers for hot-fill applications.

- The machine’s design flexibility allows manufacturers to produce containers in various shapes and sizes, from small pharmaceutical bottles to large cosmetic containers. This capability is crucial for customers who require a diverse range of products.

- High Precision and Quality:

- The ASB-70DPW features advanced control systems that ensure precise control over every aspect of the molding process, including temperature, pressure, and timing. This precision is key to producing high-quality containers with uniform wall thickness, smooth surfaces, and accurate dimensions.

- The machine’s clamping system and mold alignment mechanisms are designed to maintain tight tolerances, which is essential for producing containers that meet stringent industry standards.

- Energy Efficiency:

- The Nissei ASB-70DPW is designed with energy efficiency in mind. It utilizes advanced servo motor technology, which reduces energy consumption by optimizing the power required for each stage of the molding process.

- This energy efficiency not only lowers operational costs but also aligns with the growing demand for environmentally sustainable manufacturing practices.

- User-Friendly Operation:

- The machine is equipped with a modern user interface that allows operators to easily set parameters, monitor the process, and make adjustments in real time. This ease of use reduces the learning curve for operators and minimizes the likelihood of errors.

- The ASB-70DPW also features automated systems for mold changeovers and maintenance, further improving operational efficiency and reducing downtime.

- Global Support and Reliability:

- Nissei ASB is a globally recognized brand known for its reliable and durable machines. The ASB-70DPW benefits from this reputation, providing customers with confidence in their investment.

- The company offers comprehensive technical support and service, ensuring that customers have access to expert assistance whenever needed, which is critical for maintaining high production uptime.

- Compact Footprint:

- Despite its advanced capabilities, the ASB-70DPW has a relatively compact design, making it suitable for factories with limited space. This compactness does not compromise its performance, making it an attractive option for businesses looking to maximize production within a constrained area.

Summary

Customers prefer the Nissei ASB-70DPW for its combination of advanced technology, versatility, high precision, energy efficiency, and reliability. Its one-step process, dual-station design, and ability to handle various materials and container designs make it a versatile and efficient choice for manufacturers aiming to produce high-quality plastic containers. The machine’s user-friendly interface, global support, and compact design further contribute to its popularity among customers in industries where quality and efficiency are paramount.