Why do Customers prefer using Okuma Multus U3000 1SW 1500 CNC MultiTasking Turn-Mill Center made in Japan?

Customers often prefer using the Okuma Multus U3000 1SW 1500 CNC Multi-Tasking Turn-Mill Center for several technical and financial reasons. Here’s a breakdown:

Technical Advantages:

- Precision Engineering:

- Made in Japan: Japanese manufacturing is renowned for its precision and quality control. The Okuma Multus U3000 benefits from this high standard, resulting in a machine that offers exceptional accuracy and reliability.

- Thermal Stability: The machine is designed with thermal stability in mind, reducing the effects of temperature changes on machining accuracy. This ensures consistent performance even during long production runs.

- Multi-Tasking Capabilities:

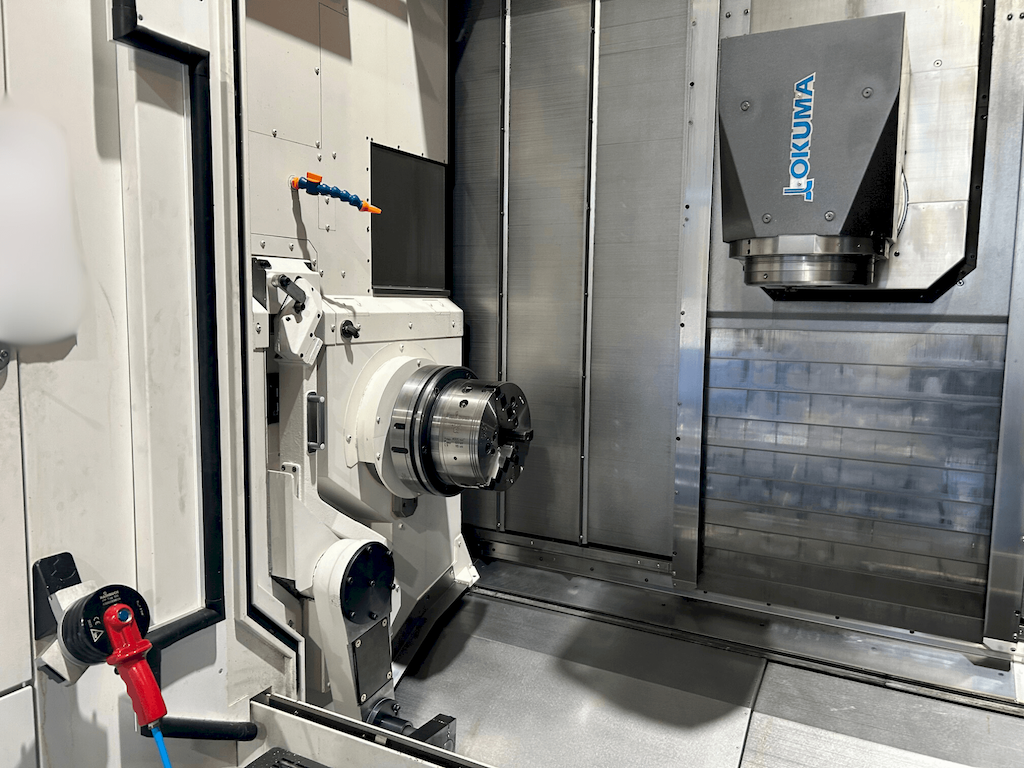

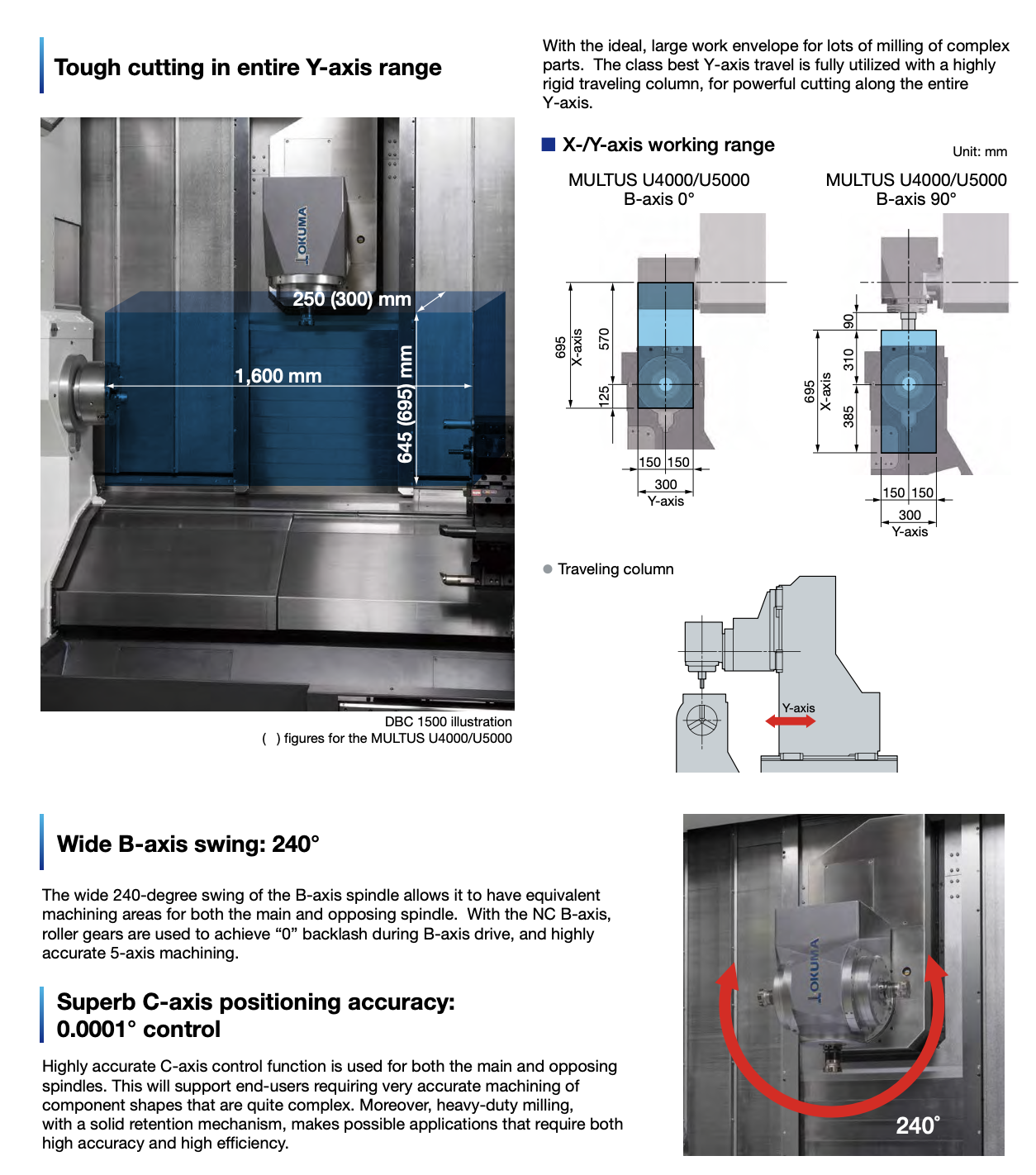

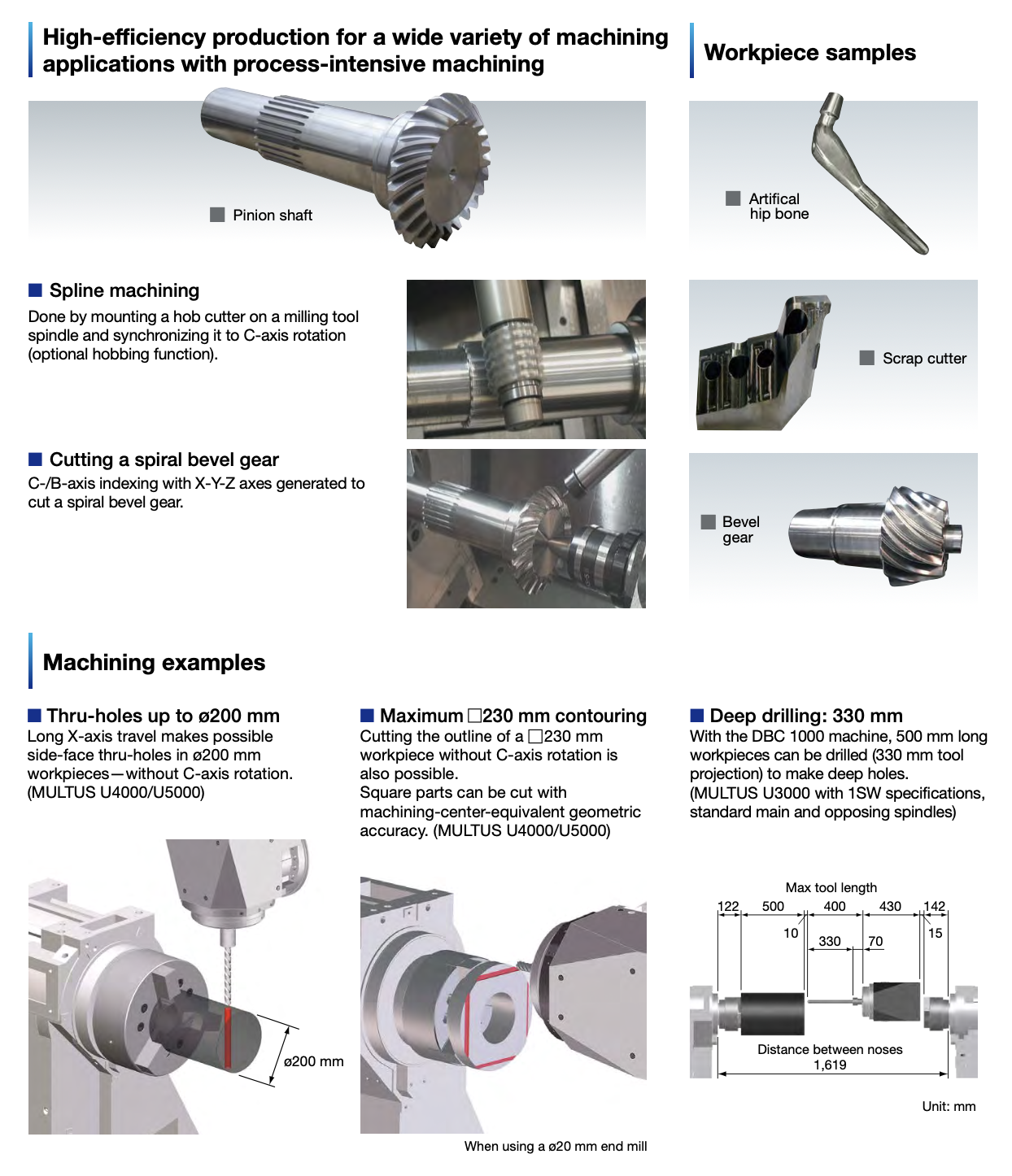

- Turn-Mill Operations: The Multus U3000 can perform both turning and milling operations in a single setup, reducing the need for multiple machines and setups. This not only saves time but also minimizes the potential for errors.

- Flexibility: The machine supports complex machining tasks, including the ability to handle parts with intricate geometries. This versatility makes it suitable for a wide range of industries, from aerospace to automotive.

- High-Speed Machining:

- Powerful Spindle: The machine is equipped with a high-speed spindle that allows for efficient material removal, reducing cycle times and improving productivity.

- Advanced Control System: Okuma’s OSP-P300 control system offers intuitive operation, high-speed processing, and advanced features like collision avoidance, which enhances both safety and efficiency.

- Build Quality and Durability:

- Robust Construction: The machine is built with a sturdy structure, which minimizes vibrations and ensures long-term durability. This is particularly important for maintaining precision over the lifespan of the machine.

- Advanced Tool Management: The machine’s tool management system allows for efficient tool changes and reduces downtime, further enhancing productivity.

Financial Advantages:

- Cost Efficiency:

- Reduced Labor Costs: By combining multiple operations in one machine, the Okuma Multus U3000 reduces the need for multiple setups and machines, which in turn lowers labor costs.

- Lower Maintenance Costs: The machine’s robust build quality and reliable performance translate to lower maintenance costs over time. Additionally, Okuma’s global service network ensures that support is readily available.

- High Return on Investment (ROI):

- Increased Productivity: The machine’s ability to handle complex tasks with high precision and speed results in higher throughput, leading to increased production output.

- Resale Value: Okuma machines, known for their durability and performance, tend to retain their value well in the second-hand market, making them a solid investment.

- Energy Efficiency:

- Optimized Power Consumption: Okuma machines are designed to be energy-efficient, which reduces operational costs. This is increasingly important as energy prices rise and companies look to reduce their environmental footprint.

- Minimized Downtime:

- Reliability: The machine’s design minimizes downtime due to maintenance or errors, ensuring that production schedules are met consistently, which is crucial for financial planning and maintaining customer satisfaction.

Reputation and Support:

- Brand Reputation:

- Okuma’s Legacy: Okuma is a well-respected brand in the CNC industry, known for innovation and reliability. Customers trust Okuma products for their critical manufacturing operations.

- Global Support Network:

- Technical Support and Training: Okuma offers comprehensive support, including training programs, ensuring that operators can fully utilize the machine’s capabilities. This reduces the learning curve and enhances operational efficiency.

Conclusion:

The Okuma Multus U3000 1SW 1500 CNC Multi-Tasking Turn-Mill Center is preferred by customers for its combination of technical excellence, cost-effectiveness, and strong support network. Its ability to perform multiple operations in one setup, combined with high precision, durability, and energy efficiency, makes it a valuable asset in modern manufacturing environments. Financially, it offers a high ROI through increased productivity, reduced operational costs, and strong resale value.